大型环形薄壁锻件调质工艺研究

打开文本图片集

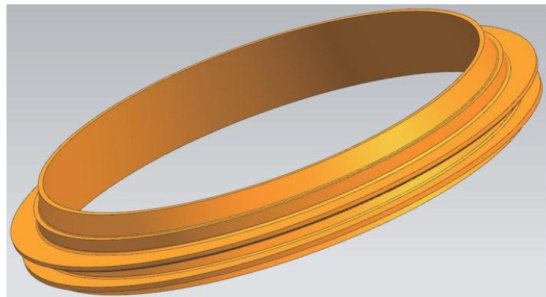

Abstract:Thematerial of thelarge annularthin-walled forging is 3OCrMnSiA steel,the maximum diameter is (20 1630mm ,the height is 230mm ,the wall thickness is about 25mm , the hardness after quenching and tempering is required to meet 33~38HRC ,and the degree of warpage deformation shall not exceed 3.28mm .Forgings are tested by using special tooling,after 900°C oil-cooled quenching and 500~520∘C tempering,the hardness value and deformation degree of multiple forgings are detected,andthe hardness value is controlld in therange of 35~ 38HRC,and the deformation is controlled with in 3.28mm .It effectively solves the problem of insufficient hardness and excessive deformation in the process of quenching and tempering of the forging,and provides an technical support for the company's production and manufacturing of this type of workpiece.

Keywords: large annular thin-walled forgings; heat treatment process; deformation; quenching and tempering

1序言

大型锻件的调质处理往往比小锻件的热处理更加困难,某大型环形薄壁锻件尾环壳体(以下简称“工件”)是固体火箭发动机上的核心零件,如图1所示。(剩余3754字)