铝合金激光角焊缝背部质量控制及检测方法的研究

打开文本图片集

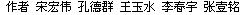

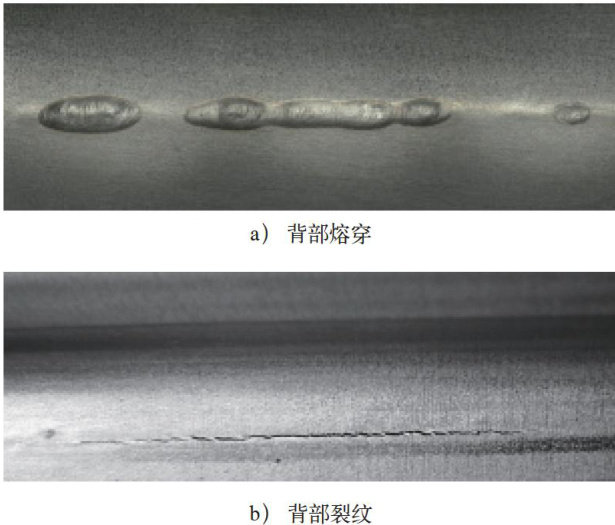

Abstract: Laser fillet welding process of automotive aluminum alloys may have defects of backside quality issues,including back melting and cracking,which affect the appearance and strength of the product.Taking the coverage area of a certain product that is prone to such problems as laser welding process experiments, macroscopic microstructure analysis of metal materials,metallographic testing,composition analysis,and other methods,this study explores the causes and paterns offailure.Studythe feasibility of online detection methods for defects such as melting through and cracking through visual measurement experiments.The results indicate that stable penetration can be avoided through appropriate parameter setings,while controllng heat input in high constraint stress areas to prevent back cracking.At high production rates,visual inspection has a high detectionrate for melting through monitoring,but more accurate detection methods need to be sought for cracking issues.

Keywords: aluminum alloy laser fillet weld; melting through; crackle; visual inspection

1序言

随着新能源汽车的快速普及,轻量化合金在车身领域的应用明显加快。(剩余4162字)