基于ANSYS的电动叉车制动端盖静力学分析与优化

打开文本图片集

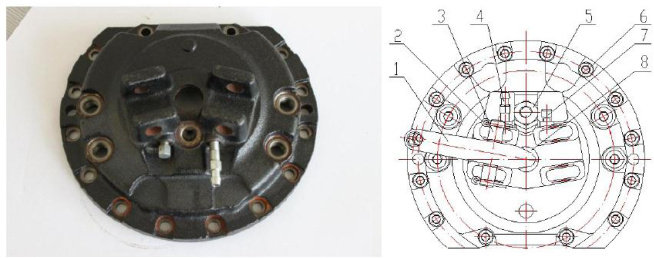

【Abstract】Toaddresstheissuesofdeformationandcrackingintheinnerringof thepistonseatboreon electric forklift brakeendcoverscaused byexcessivebrakingloadsduring parking,thisstudyemploysANSYS finiteelementanalysis (FEA) softwaretoconduct static structuralanalysisunderboth fullyloadedandunloaded conditions.Thestaticanalysis resultsre veal thatunderunloadedconditions,themaximum stressandstrainonthe innerringofthepistonseatboreremain withinthe allwablelimits,metingoperationalrequirements,andunderfullloadedconditions,themaximumstressandstrainexceed permissiblevalues,leading toyielddeformationand,inseverecases,crackingof theinnerring.Consideringtheconomic andlightweightrequirementsofelectricforklifts,anoptimizationstrategyinvolvingmoderatethickeningoftheinneringis proposed.Post-optimization staticanalysis demonstrates thatasignificantreductioninboth maximum stressand strainon the pistonseatboreinnerringandallmechanicalperformance indicators nowfallbelowallowablelimits,ensuringreliable brakingperformance.Thestudyconcludesthatstaticanalysisandoptimizationof thebrakeendcoverduring instantaneous parking braking effectivelymitigates deformationandcracking inthepistonseatbore.Thisapproachprevents braking failures and reduces unintended vehicle movement accidents,enhancing operational safety.

【Key words] ANSYS;static analysis; parking brake; brake end cover;optimization [中图分类号]TH113.2 [文献标识码]A [文章编号]1674-3229(2025)02-0068-05

0 引言

节能、轻便的三支点电动叉车被用作物流行业的主要运载工具,轮边减速器是电动叉车动力装置,实现电动叉车的传动与制动[]。(剩余4778字)