高炉粒化矿渣协同矿化封存 CO2 对充填体强度影响机制分析

打开文本图片集

关键词:碳中和; CO2 矿化;高炉粒化矿渣;固碳充填材料;微观形貌 中图分类号:TD853 文献标志码:A DOI:10.3969/j.issn.1003-9015.2024.00.018

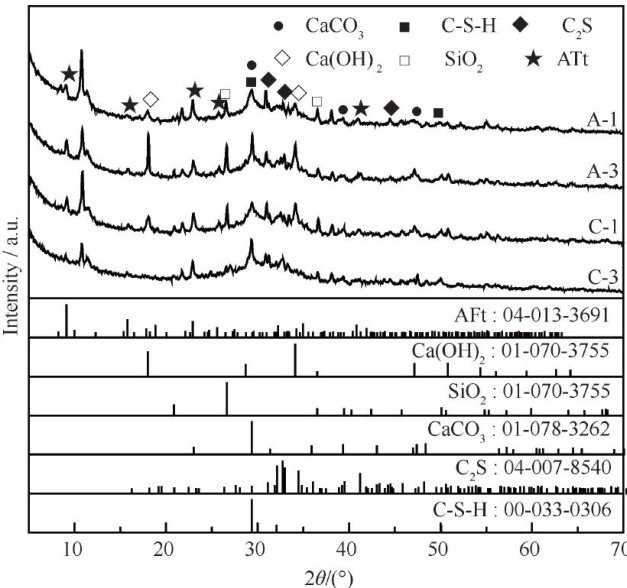

Abstract: Iron and steel production processes generate a large amount of CO2 and solid wastes such as blast furnace slag. Slag mineralization for CO 2 sequestration and its injection into goaf was proposed to solve the problems of solid wasteaccumulationand greenhouse gas emisson,whichcan efectivelycontrol the movement of rock layers and reduce ground surface colapse.This research investigated the mechanical properties,microstructure and phase composition of the slag-basedcarbon filing material(SCFM)using X-ray diffraction(XRD),scanning electron microscopy(SEM)、X-ray photoelectron spectroscopy(EDS)and thermogravimetric analysis(TG)under ambient temperature and pressure. The mechanism of CO2 curing and UCS strengthening of SCFM were analyzed. During SCFM preparation,silicate cement,slaked lime andslag powder were first hydrated,and the hydration products (hydrated calcium silicate gel and calcium hydroxide)were then carbonized with CO 2 to produce silica gel and calcium carbonate.Theresults showthat the strengthofSCFMincreasedwith theincreaseof silicatecementand slaked lime dosages,and the strength of SCFM specimens was the greatest with cement and slaked lime dosages of (204号 20% and 7% ,respectively. The strengths reached 4.41 and 16.47 MPa at the 3 d and 28d ,respectively. The maximum CO2 sequestration of 1g SCFM is 1.83mg ,which is proportional to the dosage of cement and slaked lime,and slaked lime is the controlling factor. SCFM improves solid waste and CO2 utilization and sequestration rate,which provides theoretical supports for realizing the goal of the "doublecarbon" strategy.

Key words:carbon neutrality; CO2 mineralization;blast furnace slag; carbon filling materials;microscopic morphology

1前言

政府气候变化专门委员会(IPCC)第四次评估报告指出:自1950年,人类活动及工业发展所引发温室气体排放量逐年增加,引起全球气候变暖导致生态环境问题日趋严重[1-2]。(剩余14194字)