黄铁矿流化床还原磷石膏制备 SO2 的实验及机理分析

打开文本图片集

中图分类号:X705 文献标志码:A DOI:10.3969/j.issn.1003-9015.2025.01.014

Abstract: In order to convert as much as possible S in pyrite and phosphogypsum (PG) into SO 2 ,effects of pyrite addition and reaction temperature on PG decomposition were systematically investigated using fluidized bed combined with thermogravimetricand thermodynamic calculations.The results show thatthe addition of pyrite decreases PG decomposition temperature and increases PG decomposition ratio.The most probabilistic mechanism function of the process is G(α)=1-(1-α)1/3 ,which indicates that the reaction is controlled by phase boundary.The optimized reaction condition is 30% pyrite addition at 1 100‰ for 20 min,under which the PG decomposition ratio and (204号 SO2 yield are 99.95% and 95.95% ,respectively. The by-product CaS was produced when the pyrite addition was (20号 30%~70% . When the addition was more than 70% ,solid melt Ca3Fe4S306 was produced. There are mainly two differentmechanistic paths in this process acording to diferent pyrite additions.This study enriches the process theory of SO2 preparation from reduced PG of pyrite.

Key words:phosphogypsum; pyrite; sulfur dioxide; fluidized bed; kinetics;mechanism

1前言

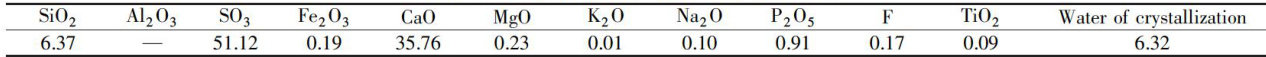

磷石膏(PG)是在湿法磷酸生产过程中,硫酸与磷矿反应产生的固体废弃物,其主要成分为CaSO4⋅2H2O[1] ,成分与天然石膏相似,但也含有少量未分解的磷矿石和加工过程中未去除的磷酸,以及一系列杂质,如 SiO2 、可溶性磷和氟化物[2]。(剩余15487字)