82B盘条拉拔后抗拉强度低原因分析

打开文本图片集

DOI :10.26915/j.issn1003-0514.2025.03.004

中图分类号:TG142.1 文献标识码:B 文章编号:1003-0514(2025)03-0011-03

Analysis of the reasons for low tensile strength of 82B wire rod after cold drawing

Zhao (Lingyuan Co.,Ltd,Lingyuan 1225Oo,Liaoning,China)

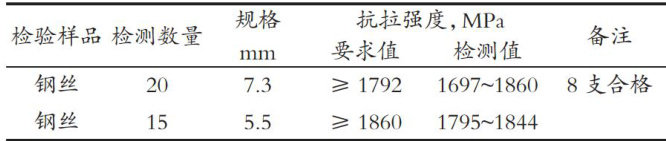

Abstract:Inorder to solve the problemoflowtensile strengthof82B stelwireaftercolddrawingfor prestressed steel strs with a diameter of Φ14mm produced by a certain steel plant,a combination of sampling inspection analysis,data comparisonexperimental verification wasadopted.The finalresults showedthatthesevere network carbide inthecore meshofthesample wasthemainreasonfor thelowtensilestrengthofthe wirerodafterdrawing.Theelectromagnetic stiing positionattheendofthecastingmachinewaslcatedattheback(inthedirectionofpullngthebilet),whichdidnotmatch theactualcentersolidphaseate of 0.1-0.2(teoptialinstallationposiionoftendelectromageticstiring)oftecasting billet.This was the mainreason forthesevere carbonsegregation inthecenterofthecasting biletthesevere network carbide in the center mesh of the wire rod.

Key Words:network carbide;tensile strength;end electromagnetic stirring position;center segregation

1前言

某钢厂2022年底开始开发生产 Φ14mm 规格82B钢,至2024年5月份前总计生产5批次约1700吨,发用户使用未反馈存在问题。(剩余2163字)