Q345R热轧钢带的生产实践

打开文本图片集

PRODUCTIONPRACTICEOFQ345RHOT-ROLLED STEELSTRIP

He Xuchu1Wang Xusheng1Mei Jie² (1.Technical Management Department of Guangxi Shenglong Metallurgical Co.,Ltd.Fangchenggang538000, China;2.Hainan Branch of China Classification Society.Haikou 57O2O3,China)

Abstract:Combining with theproduction of Q345R hot-rolled steel strip inafactory,TMCP isused toreduce the banded structure and improve the impact toughnes.The results showed that the Q345R contained a certain amount of granular bainite and the banded structure was 1.O grade,longitudinal impact SFA was more than 76.7 % ,KV2 was more than 156J at40 C ,transverse impact SFA was more than 40% ,KV2 was more than 72 Jat 40‰ ,ultrasonic testing quality grade was I on small steel plates,after annealingat 650 C for 60 minutes,the tensile strength of 16 mm steel plate is 542 MPa.Allthe test resultsmeet the standard requirements.Thefine and uniform surface structure has aimprovement efectontheimpacttoughnessof stelplates.Toensurethat thestrength meets therequirementsafter warm forming,it is recommended to control the tensile strength of Q345R within the range of 560\~620 MPa.

Key words: Q345R;hot-rolled steel strip;granular bainite;impact toughness;banded structure

0引言

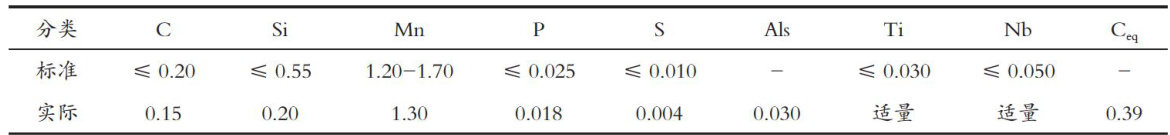

压力容器钢Q345R常见的缺陷主要有超声波探伤不合、冲击韧性不佳、强度偏低、带状、断后伸长率不合格等,其中超声波探伤不合及冲击韧性不佳主要发生在较厚的中厚板中[1.2],强度偏低发生在Q345R热轧钢带制作封头的时候,主要与热成形或温成形后强度降低有关[3.4;带状是断后伸长率不合格的主要原因[5。(剩余5279字)