新型分级轮对撞式气流磨粉碎区结构参数优化

打开文本图片集

中图分类号:TD45;TH47 文献标志码:A 文章编号:1671-8755(2025)03-0088-12

Optimization of Structural Parameter for Crushing Zone of the New Classification Wheel Collision Airflow Mill

YANG Hao',CHEN Xingyun², ZHANG Jianping',CHEN Lvjiang',NIE Bowen 1 (1. School of Manufacturing Science and Engineering, Southwest University of Science and Technology,Mianyang 62101o,Sichuan,China;2. Sichuan Shichuang Micro-nano Technology Co.,Ltd.,Mianyang 621o1O,Sichuan,China)

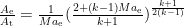

Abstract:The numerical simulation analysis method of Fluent software has been used to optimize the nozzle outlet diameter,contraction angle and nozle spacing in the crushing zone of new classification wheel collsion airflow mill. The results show that within the parameter range of nozle outlet diameter of (20 3.5-3.9mm ,contraction angle of 26∘ and nozzle spacing of 128 -144 mm,the flow velocity in the crushing zone is uniform and has long axial supersonic section length,which can achieve better particle crushing performance of collision airflow mill. Using Design -Expert software for optimization combination,the sensitivity order of structural parameters is obtained as nozzle spacing > nozzle contraction angle > nozle outlet diameter.The optimal combination of structural parameters is nozle outlet diameterof (204号 3.7mm ,contraction angle of 23∘ and nozzle spacing of 136 mm. The optimized combination of structural parameters results in the maximum length of the supersonic section and more uniform flow velocity in the crushing zone.The research results can serve as a reference for the design of the structure of the airflow crushing zone.

Keywords: Classification wheel collision airflow mill; Crushing zone;Nozzle structure; Parameter optimization

超细粉体是指细小固体颗粒的集合体,按照我国矿物加工行业的共识,超细粉体的粒径通常被定义为 100% 小于 30μm[1-2] 。(剩余13411字)