轨道车体用6061铝型材粗晶层研究

打开文本图片集

文章编号:2096-2983(2025)05-0081-06

引文格式:.轨道车体用6061铝型材粗晶层研究[J].有色金属材料与工程,2025,46(5):81-86.DOI: 10.13258/j.cnkinmme.20240920o02.WANG Yu.Research on thecoarse-grained layerof6061 aluminum profiles forrail car bodies[J]. Nonferrous Metal Materials and Engineering, 2025, 46(5): 81-86.

关键词:粗晶层;宏观金相;断口形貌;力学性能中图分类号:TG379 文献标志码:A

Research on the coarse-grained layer of 6O61 aluminum profiles for rail car bodies

WANG Yu (Liaoyang XMXYG Aluminium Co., Ltd.,Liaoyang 1110o3, China)

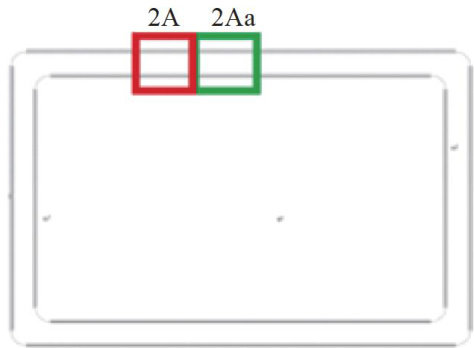

Abstract: By using equipment such as spectrometers, macroscopic metallographic corrosion devices, pressure testing machines,and electronic universal testing machines, through macroscopic metallographic analysis, fracture morphology characterization and mechanical property tests,the relationship between the microstructure and properties of 6O6l aluminum profiles used in rail car bodies was studied. The research results show that coarse recrystallized grain structure zones appear along the periphery on the transverse section of the 606l aluminum profile samples. The grain coarsening phenomenon is particularly significant at the parts with large deformation and the fusion joints. At the fusion joint, the grains are interlaced with each other,the structure is not dense and stratified. At the adjacent fusion joint, the fracture surface presents a coexisting form of concave-convex fibrous and granular sawtooth stratification. The specified plastic elongation strength at the adjacent fusion joint of sample 1 is 11MPa higher than that at the fusion joint, and the tensile strength at the adjacent fusion joint remains basically stable with that at the fusion joint. With the increase of the thickness of the coarse-grained layer at the fracture surface, the elongation of 6O6l aluminum profile samples after fracture gradually decreases.

Keywords: coarse-grained layer; macroscopic metallographic; fracture morphology; mechanicalproperty

随着现代交通工具的快速发展,对材料性能的要求越来越高[]。(剩余5307字)