AZ31B镁合金表面新型稀土铈化学转化涂层的结构与性能

打开文本图片集

中图分类号:TG174.4 文献标志码:A

文章编号:2096-2983(2025)05-0042-07

引文格式:,,,等.AZ31B镁合金表面新型稀土铈化学转化涂层的结构与性能[J].有色金属材料与工程, 2025,46(5): 42-48.DOI: 10.13258/j.cnki.nmme.20241223001.PENG Xingxing, ZHANG Wentao,XUChensheng, etal.The structureand properties of a novel rare earth cerium chemical conversion coating on thesurface of AZ31B magnesium alloy[J]. Nonferrous Metal Materials and Engineering, 2025, 46(5): 42-48.

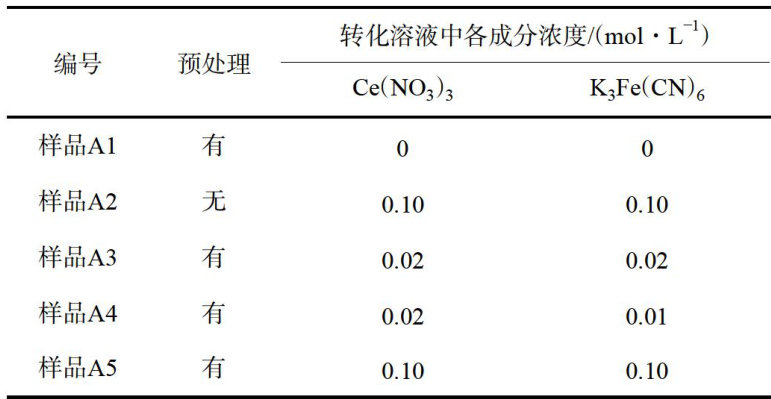

Abstract: Magnesium alloys are widely used in industrial and biomedical fields due to their properties, such as low density and high strength. However,their poor corrosion resistance limits their practical applications.The preparation of rare earth conversion coatings on the surface of AZ31B magnesium alloy was proposed by using a conversion solution containing K3Fe(CN)6 and Ce(NO3)3 , and the phytic acid pretreatment was introduced to improve the properties of the rare earth conversion coatings. The analysis results of scanning electron microscope show that the surface of the rare earth conversion coating is homogeneous and without obvious microscopic cracks. The electrochemical test results show that the prepared rare earth conversion coating has the best performance when the conversion solution is a mixed solution of 0.1mol/LCe(NO3)3 and 0.1mol/L (204 K3Fe(CN)6 .Its corrosion potential is -0.992V and the corrosion current density is as low as 1.398×10-9A/cm2 . Compared with the corrosion current density of the blank magnesium alloy (1.802×10-4A/cm2) , is reduced by approximatelly five orders of magnitude. The experimental results show that the prepared rare earth conversion coating system [especially the rare earth conversion coating prepared when the conversion solution is a mixed solution of 0.1mol/L (20 Ce(NO3)3 and 0.1 mol/L K3Fe(CN)6] exhibits excellent corrosion resistance performance.

Keywords: corrosion resistance; Ce(NO3)3 ; phytate pretreatment; electrochemical testing

镁合金具有良好的物理和力学性能,如低密度、高比强度、优异的刚性、良好的导热性和有效的电子屏蔽特性,以及可回收性和环境友好性,被广泛应用于工业和生物医学等领域[1]。(剩余8069字)