管系环焊缝射线检测透照次数计算

打开文本图片集

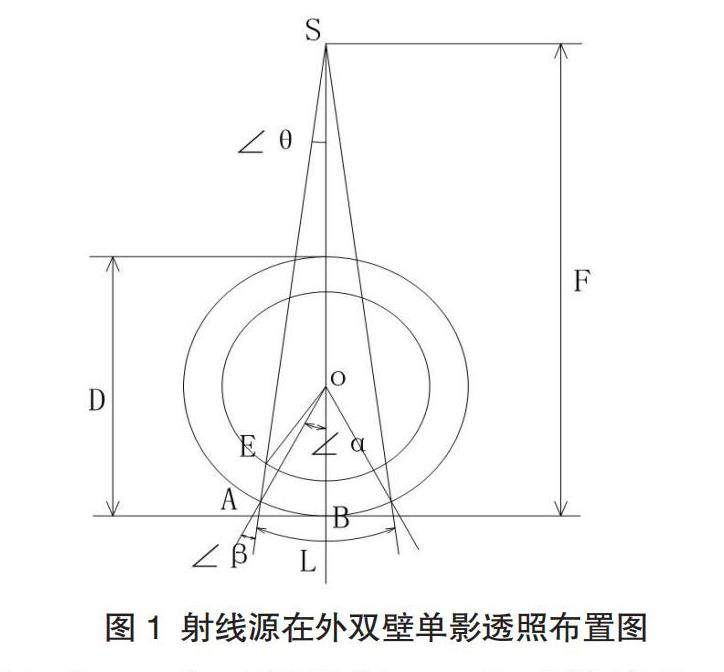

摘 要:本文讨论了ASME V和CB/T3558两个标准的相关条款,并根据工件规格及X射线机曝光曲线,计算出管系环向对接焊缝符合ASME V标准要求的一次透照长度,为现场实际操作提供参考,提高射线检测工作效率。

关键词:黑度范围;有效长度;环缝检测

中图分类号:U671.8 文献标识码:A

Calculation of Penetrate Times for Piping

Weld Radiographic Testing

GUO Dazhou, ZHANG Biao, DONG Xue, PENG Lvgao, XU Wentao

( CSSC Huangpu Wenchong Shipbuilding Co., LTD., Guangzhou 511462 )

Abstract: This paper discusses about the relevant clauses of ASME V and CB/T3558, and use workpiece specifications and X-ray exposure curve to calculate the effective length of circumferential butt weld in accordance with ASME V standard. This parameter can provide reference for the actual operation. The calculation of the maximum effective length can improve the efficiency of X-ray detection.

Key words: film density range; effective length; circumferential weld test

1 前言

我司承建的某海洋石油钻井平台,冲桩管系有大量的环向对接接头环焊缝需要进行100%射线照相检测。(剩余5540字)