腐蚀管道剩余强度计算方法研究和修正

打开文本图片集

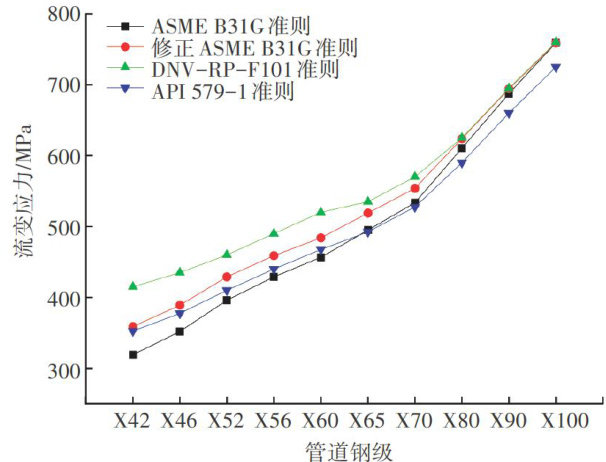

Abstract:Thisstudyaims toimprove theaccuracyandadaptabilityof thecalculationresultsof theresidualstrengthofcorroded pipelines.Afteranalingthedifereneofcommonlyusedevaluationmetods,tedifereceintedevelopmentofvoumetriccorosion defectsandcackdefects tothepasticonewasverifedbasedonfinitelementanalysisAditionalltheswellingcoefcentuder diferentequivalentdfectlengthsanddepthswasbtainedbasedontheinversecalculationmethod,andtheswelingcoffenwas revised.Finally,theerrordistributionofdiferentcalculationmethdswascalulated.Theresultsshowthattheflowstressandthe residualstrengthoftitactpipeavelilinfuenconteesialstregthofteorrdedpipehiletesellngcofnthsa greatinfluenceontheresidualstrengthofthecorrodedpipe.Whenthecorosiondepthisshallow,theplasticzonedevelopsfromthe defectend.Whenthecorosiondepthisdp,theplasticzonedevelopsfromthedefectendandthemiddlesimultaneously.Therelative errorswithin ±5% of ASME B31G standard,modified ASME B31G standard,DNV-RP-F101 standard,API579-1 standard,and the calculationresults of the proposed method were 22.03% 20.33% 38.98% 22.03% ,and 55.93% ,respectively.Therefore,thismethod is of higher practicality.

Keywords:corrosion defect; residual strength;flow stress; swelling coefficient; pipeline; crack defect

油气管道在服役过程中,受输送介质、土壤性质、大气环境、杂散电流等因素的影响,不可避免地会发生不同程度的腐蚀,导致壁厚减薄、承压能力下降,一旦发生穿孔泄漏,将会引发严重的经济损失和环境破坏[1-2]。(剩余6289字)