伴生气凝液回收与液化工艺联产技术研究

打开文本图片集

DOI:10.3969/j.issn.1001-2206.2025.03.011

Research on co-production technology of condensate recovery and liquefaction process of associated gas

LIU Haiying Sulige Exploration and Development Branch of Huabei Petroleum Administration Co.,Ltd.,Ordos O17004, China

Abstract:Insomeoilfields,asociatedgasisusuallydirectlyventedduetodispersed gassources,smallgasvolume,andremote distancefromthegastransmisionnetwork,resulting inresourcewasteandenvironmentalpolution.Torealizetherecoveryand comprehensiveutilizationofasociatedgas,theprocessesofcondensaterecoveryandliquefactionwerecombinedandsharedaseof refrigerationcclestoformacoproductionproessofthegassubcooledprocess(GSP)andsteammethanereforming (SMR)andthe redundantequipmentintheproceeswassimplified.Theinfluenceofchangesintheco-productionprocessparametersonthpecific power consumption, liquefaction rate, and C2+ recovery rate was analyzed.Finally,the differences between the single production process andco-productionprocesswerecompared.Theresultsshowthatthelowertmperatureofthelow-temperatureseparatorindicatesthe the higher tower pressure of the demethanizer,smaller gas-phase split ratio,lower specific power consumption and C2+ recovery of the co-productionprocs,andigerliquefactionrate.Teinfueneoftheixingrefrigerantatioonspecificpowerconsumptiondepnds onthechangeofomponentswithalowerboilingpoint.Byotiizingtemiingrefrigerantatioflowrateandrefrigerantpreuete specific power consumption can be greatly reduced. The specific power consumption, liquefaction rate and C2+ recovery of this process are 0.501 4 kW·h/kg, 91.21% and 85.55% ,respectively. Compared with those of the contrast process,the number of equipment is smaller,and the heat transfer of the cold boxis less required.

Keywords:condensate recovery; liquefaction; GSP; SMR; co-production; specific power consumption

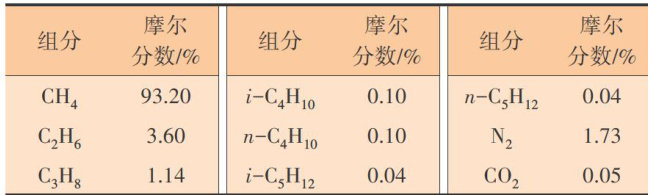

随着国家“碳中和”“碳达峰”目标的提出,推动传统能源行业转型、大力推广清洁能源成为当前油气田企业发展的重要方向。(剩余5754字)