基于复合工艺优化的伴生气脱酸技术研究

打开文本图片集

Deacidification technology for associated gas based on composite process optimization

LIU Tao

SafetySupervisionandetectionCenter,HuabeiOilfieldCompany,ChinaNationalPetroleumCorporationLimited,enqiu652,

China

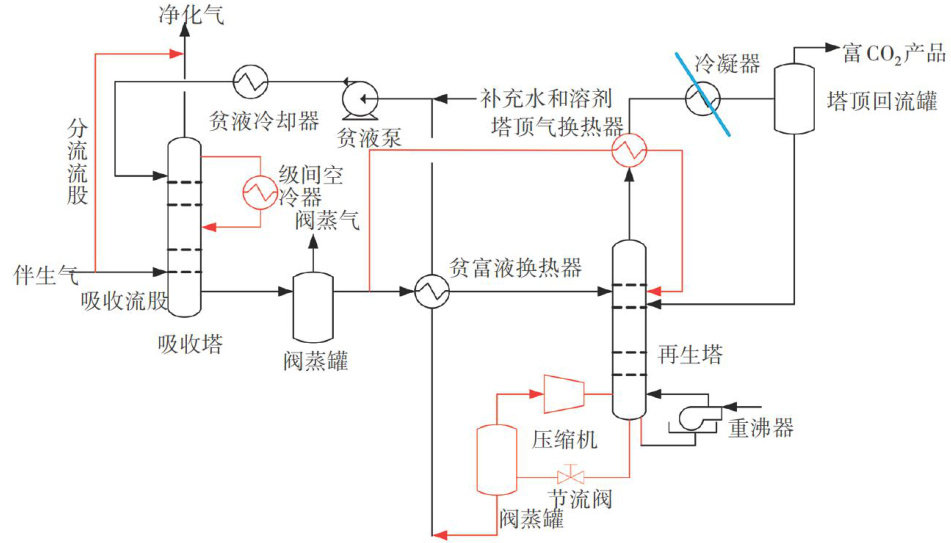

Abstract:Toreducetheprocsseergconsumptionintedeacidificationprocessforasociatedgasbythetraditionalalcoholaine absorptionmdtizatidutoptcdorlqdateagesellasgenatiode traditionalprocess.Underthepremiseoffxedpurifiedasqalityteifluenceofchangs incompositeprocesparametersoeergy consumptionwasanalyzedbasedonsimulationsoftware.Theoptimalcomposite processcombinationwasdeterminedwhilethe key productparameters,keyequipmentsize,ndeconomywereevaluated.Theresultsshowthattheextractionpositionof theinterstage colingirculationflowshouldbekeptatthe13thtrayandtheinterstagecolingtemperatureshouldbethelowestwithinthe requirementforteeatexchangeperformance(33C).Teenergyconsumptionleveloftecompositeproessreachditsigstwith theraw gassplitratio of 25% ,therichliquidsplitratioof 10% ,andthesecond rich liquid inlet position beingat the fifth tray.Lean liquid throttle pressure should be the lower limit ( 70kPa ). The optimal composite process is interstage cooling + rich liquid splitting + rawgas spliting.Compared with the traditional process,the energy saving rate of this composite process is 25.35% . The product quality of the optimalcomposite processis better than thatofthe traditional process,with apayback period of 1.59 years.

Keywords:associated gas;deacidification; alcohol amine solution; absorption tower; regeneration tower

天然气作为一种优质的清洁过渡能源,在一次能源中的占比大幅提升[1]。(剩余5822字)