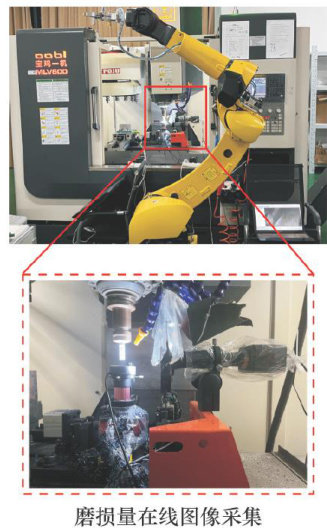

基于空间注意力机制U-Net的铣刀磨损在位监测方法

打开文本图片集

关键词:U-Net模型;注意力机制;机器视觉;铣刀;磨损监测

中图分类号:TP181;TH164

DOI:10.3969/j.issn.1004-132X.2025.11.030

Abstract:To address the issues of high workload and low accuracy in existing machine vision-based off-line tool wear measurement,an in-situ monitoring method for milling tool wear in machining centers was proposed based on a spatial attntion mechanism U-Net. Firstly,an automatic tool wear monitoring experimental platform was established. Through PMC programming,the platform employed NC codes to control spindle orientation and rotation angles,enabling automatic positioning of the wear areas on the lateral cuting edges of the milling cutters. Secondly,communication with the machine tool through the Focas protocol and C# scripts,automatic in-situ imaging of the milling cutter's bottom edge and each lateral edge were realized. Next,label files were created by using LabelMe software,the spatial attention mechanism U-Net semantic segmentation method was employed to accurately identify the wear areas,and the quantifiable tool wear values were obtained by combining the morphological method. Finally,the proposed model was compared with semantic segmentation models such as Deeplabv 3+ ,full convolutional networks (FCN),Lraspp, SegNet,and PspNet to verify the effectiveness and accuracy of the proposed method.

Key words: U-Net model; attention mechanism;machine vision;milling tool; wear monitoring

0 引言

刀具是机械加工装备中至关重要的组成部分。(剩余11722字)