CAD图形制导的汽车轮毂机器人打磨路径生成方法

打开文本图片集

关键词:汽车轮毂;机器人;打磨路径;姿态优化

中图分类号:U468.22;TP242

DOI:10.3969/j.issn.1004-132X.2025.11.028

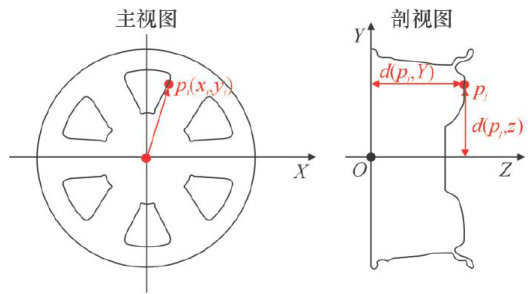

Abstract: An adaptive generation method of robotic grinding paths guided by CAD drawings was pro posed to remove burrs on wheel hub hole side edges smoothly,addressing inconsistent raw materials,missing 3D models,and only 2D CAD drawings.First,theoretical grinding paths were quickly extracted based on point correspondences between CAD main and sectional views,and actual 2D hole contours were acquired using a 2D industrial camera.Aregistration model between the theoretical paths and actual contours was established,and a neighborhood-based weighted averaging method was used to restore depth information of the actualcontours,generating adaptive grinding paths. Then,B-spline curve fiting was applied to smooth path points,and a spherical quadrilateral interpolation model was used to optimize tool orientations,ensuring continuous and smooth grinding in high-curvature or chalenging regions. Experimental results show that the generated paths are continuous,smooth,and tool orientations remain stable. Compared with theoretical paths,path accuracy is improved by over 90% , and the average production cycle is as 88s , meeting industrial requirements.

Key words: automobile wheel hub;robot; grinding path;posture optimization

0 引言

在汽车轮毂铸造和机加工过程中,侧缘常残留飞边及毛刺,其清理对外观、定位精度及行驶稳定性至关重要[1-3]。(剩余12696字)