电脉冲辅助硬车淬硬轴承钢表面摩擦学性能研究

打开文本图片集

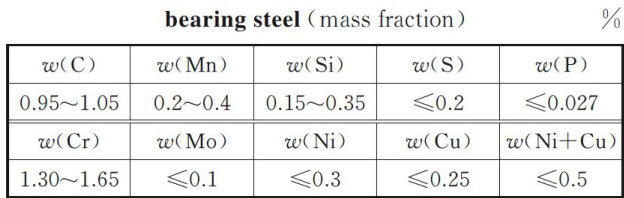

关键词:淬硬轴承钢;电脉冲辅助硬车;硬车加工性能;表面完整性;耐磨损性能中图分类号:TG51;TG142.1DOI:10.3969/j.issn.1004-132X.2025.11.008

Abstract:The poor hard turning performance of hardened bearing steels significantly reduced the sur face integrity of the workpieces,resulting in poor friction and wear performance ofhardened bearing steels. Based on the superiority of electric pulse asisted cuting technology,the surface integrity and surface wear resistance of hardened bearing stels were studied. The results show that the surface integrity of the workpieces is improved significantly,the friction coeficient is reduced by 20% ,the width and depth of the wear scar are reduced by 48.7% and 93.33% respectively,and the friction and wear performance of the hardened bearing steels is significantly improved.

Key Words: hardened bearing steel; electric pulse assisted hard turning;hard turning performance; surface integrity;wearresistance

0 引言

轴承钢材料需要淬火处理以提高轴承套圈的硬度与耐磨性,淬硬轴承钢硬度在6OHRC以上,切削加工性能极其恶劣[],淬硬轴承钢硬车加工一直是近几十年来的研究热点问题[2]。(剩余12477字)