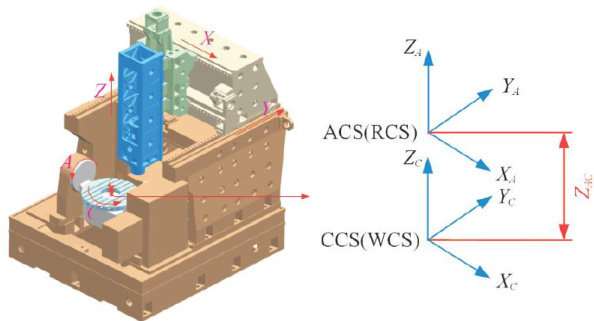

一种五轴机床旋转轴位置无关几何误差辨识方法

打开文本图片集

关键词:五轴机床;旋转轴;位置无关几何误差;球杆仪;安装模式中图分类号:TH161DOI:10.3969/j.issn.1004-132X.2025.11.016

Abstract: In order to quickly identify PIGEs of rotary axis of five-axis machine tools,and improve the accuracy in identifying geometric errors of rotary axis,a simple identification method was proposed for PIGEs of rotary axis using three installtion modes of DBB. The mathematical model of bar length changes included instalation errors and PIGEs of rotary axis was established based on homogeneous coordinate transformation under three installation modes of DBB.The efects of PIGEs on the paths of DBB were analyzed by simulation under three installation modes,and the results show that eight PIGEs may be identified by controling uniaxial motion under three installtion modes. In the identification experiments,the influences of identification accuracy were eliminated by measuring the instalation errors of DBB,and the dentification of eight PIGEs of rotary axis was realized. Finally,eight PIGEs of rotary axis were compensated, and the experimental results show that the maximum absolute value of the compensated erors is reduced from 103.9μm to 0.46μm ,which verifies the effectiveness and accuracy of the proposed identification method.

Key words: five-axis machine tool; rotary axis; position-independent geometric error(PIGE);doubleball bar(DBB);installation mode

0 引言

五轴机床相比三轴机床具有更好的灵活性,可以加工涡轮叶片、发动机缸体等复杂零部件,但两个旋转轴的增加引人了更多误差,影响五轴机床的精度。(剩余12120字)