基于细观仿真建模的CFRP纵-扭超声铣削材料去除机理研究

打开文本图片集

关键词:碳纤维增强树脂基复合材料;纵-扭超声振动;细观仿真;材料去除机理;纤维方向角中图分类号:TH162;V258DOI:10.3969/j.issn.1004-132X.2025.04.013 开放科学(资源服务)标识码(OSID):

Material Removal Mechanism of CFRP in Longitudinal-torsional Ultrasonic Milling Based on Mesoscopic Simulation Model

ZHANG ChaolREN Yinghui1,2*YU Xiaolin1LI Maojun²YU Chengyang²DU Xinliang1 1.School of Mechanical Engineering,Shenyang Ligong University,Shenyang,110159 2.College of Mechanical and Vehicle Engineering,Hunan University,Changsha,

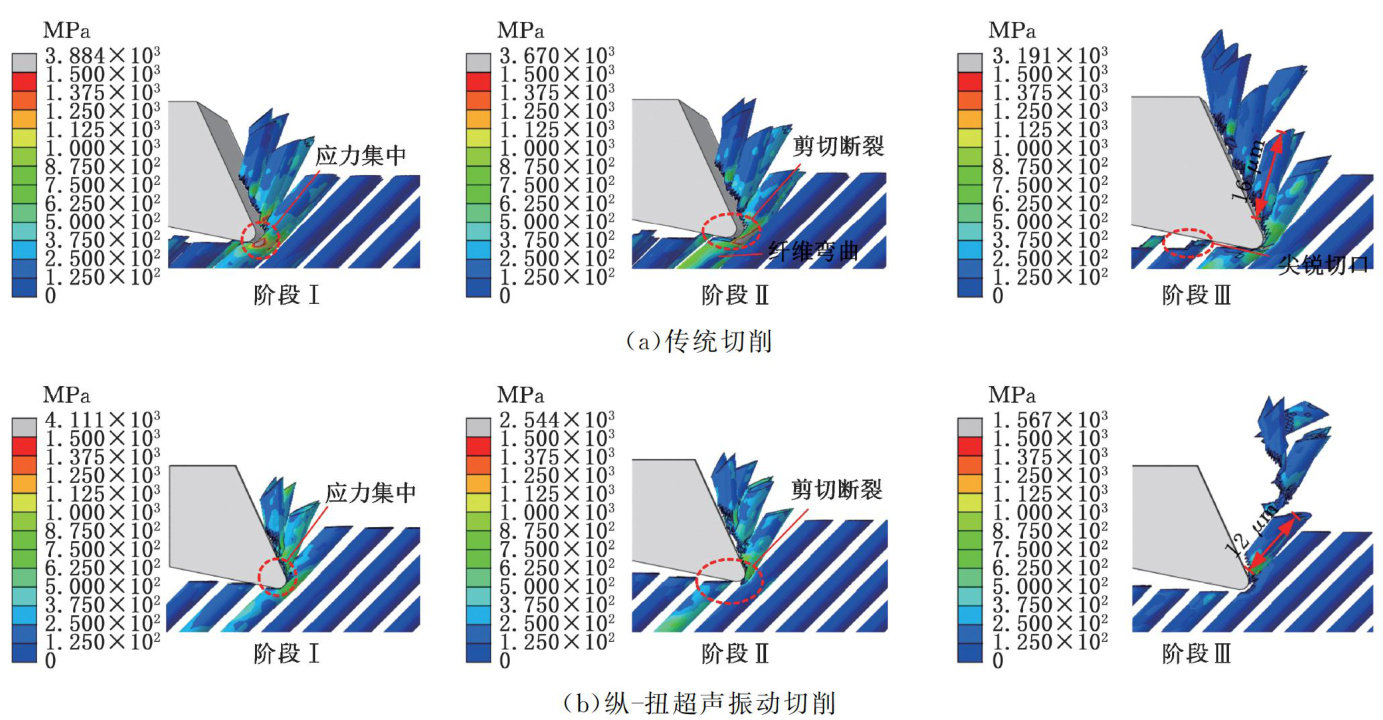

Abstract: In order to reveal the material removal mechanism of CFRPs in longitudinal-torsional ultrasonic vibration milling,a simulation study of CFRP mesoscopic-cutting was carried out. The kinematic characteristics of longitudinal-torsional ultrasonic vibration miling were analyzed,and a 3D mesoscopic-cutting model of CFRPs was established. The fiber removal mechanism, matrix damage, chip morphology and cutting force of conventional cutting and longitudinal-torsional ultrasonic vibration cutting were compared under different fiber orientation angles. The results show that when the fiber orientation angle is 0∘ , the longitudinal-torsional ultrasonic vibration cutting impact characteristics accelerate the fiber bending processes,and the fiber removal mechanism at the cuting-edge changes from conventional rolling to scratching. When the fiber orientation angle is 45∘ and 90∘ ,the impact characteristics enhance the shear effects of the cutting-edge on the fiber,especially when the fiber orientation angle is 90∘ . When the fiber orientation angle is 135∘ ,the fiber removal mechanism changes from large area bending to local fracture.Longitudinal-torsional ultrasonic vibration miling is beneficial to restrain matrix damage,improve chip morphology and reduce heat accumulation in the cutting areas and decrease the average cutting forces. The experiments verify the accuracy of the simulation analysis.

Key words:carbon fiber reinforced polymer(CFRP);longitudinal-torsional ultrasonic vibration; mesoscopic simulation;material removal mechanism; fiber orientation angle

0 引言

碳纤维增强树脂基复合材料(carbonfiberreinforcedpolymer,CFRP因强度高、质量小、耐腐蚀和抗疲劳性好等优势,在航空航天、汽车制造及医疗等领域得到了广泛应用[1]。(剩余14014字)