纳米碳球切削液的润滑性能及机理研究

打开文本图片集

中图分类号:TB34;TH140 DOI:10.3969/j.issn.1004-132X.2025.04.008

Study on Lubricating Performances and Mechanism of Nano-carbon Balls Cutting Fluids

SUN Hao¹ LAN Qixin² YAO Bin2* LU Jingjing1 ZHANG Jinhui² PAN Zhirong² ZHAO Kexin² 1.AECC Harbin Dongan Engine Co.,Ltd.,Harbin,150060 2.School of Aerospace Engineering,Xiamen University,Xiamen,Fujian,361005

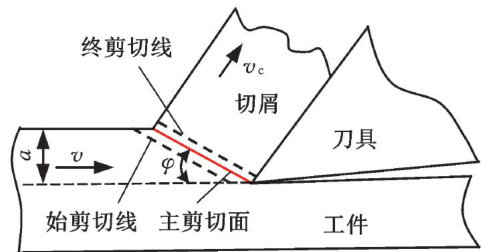

Abstract: Nano-carbon balls cutting fluid was applied to the cutting processes of difficult-to-machine aerospace gear steels (15Cr14Co12Mo5Ni2W) ,and the lubrication enhancement effects of nanocarbon particles on the cutting fluid were investigated.Firstly,a cutting force model for metal cutting was established to analyze the relationship between cutting lubrication and cutting forces. Furthermore,through combined friction-wear tests and milling experiments,the lubrication performance of nano-carbon balls cutting fluid was evaluated in terms of friction coefficient,wear volume,friction surface quality,and cuting forces. Compared with the base cuting fluid,when the mass fraction of nano-carbon is reached 0.02% ,the milling forces for the gear steels are decreased by over 10% ,and surface roughness is reduced by more than 15% . Experimental observations reveal that nano-carbon particles on the friction contact surfaces preferentially are adsorbed onto micro-peak regions with higher surface free energy,forming a nano-carbon adsorption film.Lubrication mechanism analysis indicates that this adsorption film may exert a friction-reducing“micro-bearing” effects.

Key words: nano-carbon ball;cutting fluid; lubrication mechanism; miling; difficult-to-cut gear steel

0 引言

难加工金属材料的切削存在切削力大、切削温度高、刀具磨损/破损严重等问题,使得切削质量较难控制。(剩余16638字)