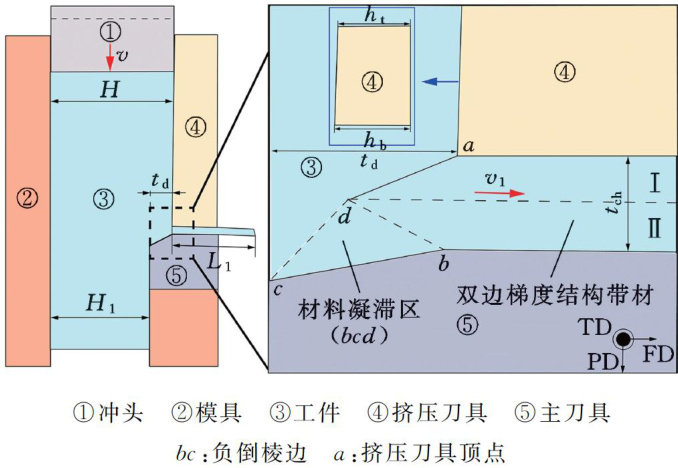

挤压-切削制备可控厚度的双层梯度结构带材的新工艺及机理

打开文本图片集

关键词:挤压-切削;可控厚度;双层梯度结构;梯度超细晶带材;机械性能中图分类号:TG376DOI:10.3969/j.issn.1004-132X.2025.04.010 开放科学(资源服务)标识码(OSID):

New Process and Mechanism of Squeeze-machining for Preparing Bilateral Gradient Structure Sheets with Controllable Thickness

PANG Xueqin1,² ZHAO Junyu1 DENG Wenjun² ZENG Yuning² ZHONG Peixuan2* 1.Faculty of Electrical and Mechanical Engineering,Kunming University of Science and Technology, Kunming,650500 2.School of Mechanical and Automotive Engineering,South China University of Technology, Guangzhou,510641

Abstract : To address the issues of high strength but low ductility in ultrafine-grained materials,a unique squeeze tool and extrusion channel design was developed. This design enabled the one-step fabrication of ultrafine-grained sheets with a controllable thickness and a bilateral gradient structure through the combined effects of squeeze,friction and cutting. The numerical simulation and experimental methods were combined to analyze the forming processes of bilateral gradient structured pure copper sheets. The mechanism of squeeze-machining machining and the influences of processing parameters on the formations of the bilateral gradient microstructure were explored. The results show that,compared to the original pure copper samples,the maximum hardness of the pure copper sheets prepared using the squeeze-cutting method is increased by approximately threefold. Additionall,the sheets exhibit an excellent strength-ductility synergy: while some ductility is sacrificed, the yield strength nearly is of doubles,and the ultimate tensile strength increases by a factor of four.

Key words: squeeze-machining; controllble thickness; bilateral gradient structure; gradientultra-fine-grained sheet;mechanical property

0 引言

强度-延展性的协同是金属材料发展和应用中的一大障碍[1]。(剩余15149字)