高体积分数SiCp/A1复合材料电解-机械组合低磨损加工方法研究

打开文本图片集

关键词:铝基碳化硅复合材料;电解加工;工具磨损;金刚石磨棒

中图分类号:TG662

DOI:10.3969/j.issn.1004-132X.2025.04.012 开放科学(资源服务)标识码(OSID):

Study on Low Wear Machining Method of High Volume Fraction SiCp/Al Composite Materials by ECM-mechanical Combined Machining Processes Method

HE Bin*ZHOU Xingyu LU Hongyu ZHANG Junfei DING Kai LI Qilin LEI Weining School of Mechanical Engineering,Jiangsu University of Technology,Changzhou,Jiangsu,213001

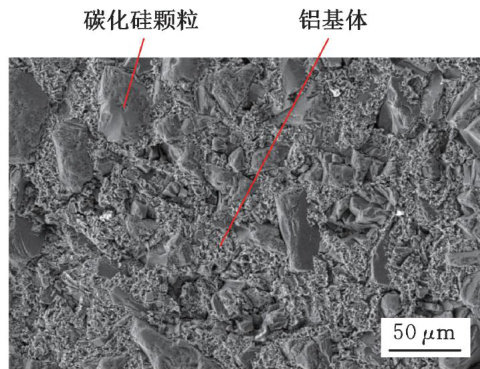

Abstract: To improve the problems of tool wear,poor surface quality and low machining efficiency of aluminum-based silicon carbide(SiCp/Al) composites with high volume fraction under conventional machining,an ECM-mechanical combined machining method was proposed,and the ECMmechanical combined machining experiments of 60% volume fraction SiCp/Al composites were carried out. The results show that SiC particles are exposed on the surfaces with the removal of aluminum matrix.There is a certain depth of transition zone between the surface of the workpiece and the matrix after ECM,the aluminum matrix in the transition zone is locally removed,and the binding force of SiC particles is reduced. When the diamond grinding rod is used for machining the transition zone,the aluminum matrix adhesion phenomenon is not observed,the diamond grinding rod has almost no wear,and the surface damages are obviously reduced. The machinability of high volume fraction SiCp/Al composites may be improved by ECM-mechanical machining processes.

Key words: aluminum-based silicon carbide composites(SiCp/Al); electrochemical machining (ECM) ;tool wear;diamond grinding rod

0 引言

铝基碳化硅(SiCp/AI)复合材料以铝(AI)金属为基体,碳化硅(SiC)颗粒为增强相,具有强度高、耐磨性优、密度小、膨胀率低、导热性强等特性,广泛应用于航空航天、汽车工业、机械设备制造、电子电气、轻量化应用等领域[1-4]。(剩余10784字)