AZ31B镁合金CMTCycleStep焊接接头组织和性能研究

打开文本图片集

中图分类号:TG444 文献标志码:B DOI:10.19710/J.cnki.1003-8817.20240407

Research on the Microstructure and Properties of AZ31B Magnesium Alloy CMT Cycle Step Welded Joint

Huang Changjun', Tang Weineng',Wu Lei', Han Mingming² (1.TechnologyCente,BaosteelMetalCo.,td.,hanghaOo94O;2.WeldingBusinessUnit,FronusItellgentEqipt (Shanghai) Co.,Ltd., Shanghai 200940)

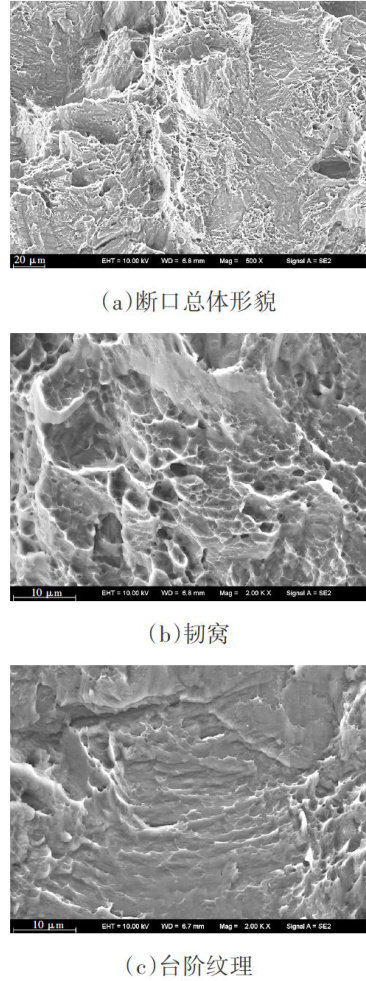

Abstract:This paper investigates the microstructure,mechanical properties and elemental distribution of welded joints using the CMT Cycle Step process with AZ81 filer wire for AZ31B magnesium aloy extruded plates to develop newwelding technologiesfor magnesium aloys.Comprehensive characterization isperformed throughoptical microscopy,Vickers hardness tester,tensile testing machine,Scaning Electron Microscopy (SEM)and EnergyDispersive X-ray Spectroscopy (EDS).Theexperimental results demonstratethatuniformand regular fish-scale patterns are formed on the weld surface.The weld zone primarily consists of α-Mg phase with discontinuous eutectic structures at grainboundaries.WhileZnelement distribution shows no significant concentration diferenceacross the base metal,fusion zone,andweld zone,Al element exhibitsmarkedly higherconcentration intheweld region compared tothe base material.The maximum hardness is observedinthe weld zone,with adistinct softening phenomenon characterizedbysignificant hardnessreduction intheHeat-Affected Zone (HAZ).The tensilestrengthof the welded joint reaches levels comparable to the base material.Tensile fractures occur in the HAZ,presenting pure shear fracture surfaces with morphological features indicative of ductile fracture characteristics.

Keywords:Magnesiumalloy,CMTCycle Stepprocess,Metallographic structure,Mechanical properties, Fracture morphology

1前言

的比强度和比刚度、良好的阻尼性能、可循环再利用性、较好的电池屏蔽性和优异的加工性能,在航空航天、交通运输、3C电子、军工和能源等领域展镁合金作为最轻的金属结构材料,具有较高现出广阔的应用前景[1-3]。(剩余6115字)