包芯纱基摩擦电织物的制备及性能

打开文本图片集

中图分类号:TS106.4;TM919 文献标志码:A 文章编号:1671-024X(2025)03-0055-06

Preparation and properties of triboelectric fabrics based on core-spun yarn

YAN Jing1,², 1,2 ,WANG Haoxuan 1,2 (20 (1.School ofTextile ScienceandEngineering,Tiangong University,Tianjin3Oo387,China;2.Research CenterforFuture Textile Technology,TiangongUniversity,Tianjin 3Oo387,China)

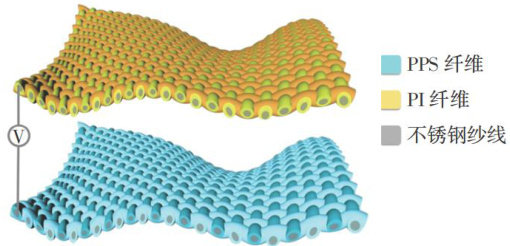

Abstract:Inordertoachievetheefectivecombinationofthetriboelectriclayerandtheelectrodeintextilebasedtriboelectric nanogenerators (TENG),the core-spun yarns with polyimide(PI)or polyphenylene sulfide(PPS)as triboelectric material and stainless-steel yarnas electrode were prepared using conjugate-electrospinning orcontinuoushollow spindle fancy twisting technology.Then,the triboelectric fabricswith full weft were prepared by weaving processin which thecore-spun yarns served asthe weft yarns.The efectoffriction layer microstructure on the performance of the TENG,the working adaptabilityof the TENG in high-temperature environment,and the practical application performance of the fabric based TENG were investigated.The results show that when PPS staple fiber core-spun yarn based fabric and PI nanofiber core-spun yarn based fabric were respectively the positive and negative triboelectric layers of the TENG,because of the effective matching between micro-and nano-fibers to increase the efective working area,the fabric based TENG showed the optimum triboelectric properties,and it could maintain stable operation in a high-temperature environment below 200 C .When the load resistance was 20MΩ ,the TENG has a power density of 0.67W/m2 and could light up 18 COBs or 140 LEDs,or charge capacitors to further power calculators,demonstrating its potential applications in the field of powering wearable microelectronics.

KeyWords:triboelectric fabric;core-spun yarn;polyimide;polyphenylene sulfide; thermal resistance

摩擦纳米发电机(triboelectricnanogenerator,TENG)通过结合摩擦起电和静电感应效应,可以有效地将周围环境和人体活动中的机械能转化为电能,有望取代传统电池为小型电子设备供电[-4。(剩余10014字)