基于机器视觉检测的焊接双臂协作机器人变质心补偿控制方法

打开文本图片集

中图分类号:TB9;TP242 文献标志码:A 文章编号:1674-5124(2025)06-0089-08

Control method of metamorphic center compensation for welding dual-arm cooperativerobotbased on machine vision detection

LI Jing',YUAN Yunmei¹,QIN Lixia',DUO Huaqiong² (1.School ofInformation Engineering,Shanxi CollgeofApplied Science and Technology,Taiyuan O30062,China; 2. School of Materials Science and Art Design, Inner Mongolia Agricultural University, Hohhot Olo018, China)

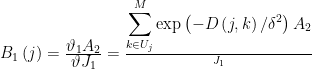

Abstract: The spoilage center compensation control method of welding two-arm cooperative robot based on machine vision detection was studied to improve the tracking accuracy of welding operation and ensure the welding quality.The welding images of target robots were collected by machine vision detection method. After removing the noise in such images with non-local mean algorithm,high-quality machine vision inspection robot images were obtained by segmentation. The basic dynamics model of the target robot was built based on such images,and the metamorphic core model was established. An adaptive sliding mode controller is designed based on the metamorphic core model to compensate and control the metamorphic core in robot welding. The results show that the machine vision image obtained by this method has high quality and good rendering effect. After compensating and controling the spoilage core in the welding operation of the experimental robot, the robot can accurately track the different directions of the mobile platform to ensure the overall welding quality. Keywords: machine vision inspection; work with both arms; welding robot; metamorphic center compensation; non-local mean; sliding mode controller

0 引言

随着智能机器人的不断发展,当前越来越多领域内应用到智能机器人。(剩余9788字)