热处理工艺对高速钢冲头组织与残余应力分布的影响

打开文本图片集

中图分类号:TG156.2 文献标识码:A DOI:10.7535/hbkd.2025yx06008

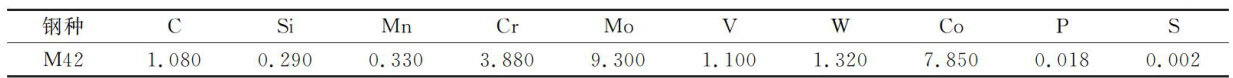

Abstract:Tooptimize the heat treatment processand enhance theperformance of M42 high-speedstel punches,which are pronetoedgecollapsefilureduringserviceduetoresidualstress,this studysystematicall investigatedtheregulatoryectof spheroidizing annealing pre-treatmentonthe microstructureandresidual stressdistributionin M42 high-speed steel punches throughoutthecompletequenching and tempering processchain.Two heattreatment routes,withand without spheroidizing annealing,weredesigned.Scanning electronmicroscopy(SEM)and X-raydifractometry(XRD)wereemployed tocharacterize the microstructure and surface residual stress of the punches at diferent process stages,and ABAQUS finite element software wasusedtosimulate theresidual stress evolution during theentire proces.Theresultsshowthatspheroidizing annealing can release 70%~90% of the initial residual stress introduced by extrusion processing and significantly improve the stress distributionafterfinalheattreatment.Notably,atthecriticalrootarea wherethepunch ispronetofilure,thestress state is optimized from a compressive stress of -400 MPa to a tensile stress of +100MPa ,which is beneficial for counteracting the service loads.Concurrently,spheroidizingannealing significantlyenhances the proportionoffinecarbides smaller than 1.5μm (2号 inthe microstructure,exhibiting a uniform and dispersed distribution.Adding spheroidizing annealing pre-treatmentisan efectivemeans tooptimizetheresidualstress distributionandrefinecarbidesinM42high-speedsteelpunches.This study reveals its underlying mechanisms and provides reference forthe heattreatmentprocess designof high-performance punches.

Keywords:heat treatment;M42 high-speed stel(HSS);spheroidizingannealing;residualstress;carbide refinement;finite element simulation

高速钢(high-speed steel,HSS)因其卓越的硬度、耐磨性及热稳定性,成为制造高效精密冲头和刀具的优选材料[1]。(剩余14026字)