柴油机活塞销孔疲劳强度影响因素研究

打开文本图片集

中图分类号:TK422 文献标识码:A DOI:10.7535/hbkd.2025yx06002

Abstract:To studytheinfluence lawof piston pinhole profileand innerdiameteron pinholefatigue strength,a finite element simulation modelof pistonandcomponentswas established.Theoptimal matchingschemeof pinholeprofileandpistonpin, verified byengine bench test,wasobtained bysimulatingandcalculating how diferent pinhole profilesand piston pininer diametercan afectthepinhole pressureandfatiguestrength.Theresults show that thepinholeprofilesdo havegreater influenceonthecontactpresureandfatiguestrengthinthepinhole;Thepistonpininnerdiametermainlyaffects fatiguestrengthofpinholeand pin,aswellas eliptical deformationof pistonpinrather than thecontact pressureof piston pin. For every 1mm increase in the inner diameter of piston pin,the fatigue coefficient of pinhole will decrease by 6.2%~ 11.2% ,the elliptical transformation of piston pin will increase by 10%~15% ,and the fatigue coefficient of piston pin will decrease by 3.2%~9.8% . Therefore,it can improve the fatigue strength of pinholes and reduce the risk of pin hole cracking andfailureefectivelybyadjustingthehyperboloidal shrinkageofpinholeprofileanddecreasingthepistonpininnerdiameter, whichprovidestheoreticalandengineringapplicationreferencesforimprovingthereliabilityofinternal combustion engine pistons.

Keywords:internalcombustionengineenginering;fatigue strength;dieselengine;piston;pinhole;finiteelementsimulation

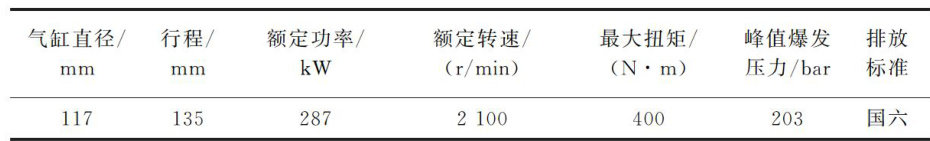

随着发动机向高功率、低排放的方向发展,其爆发压力也随之提升。(剩余11533字)