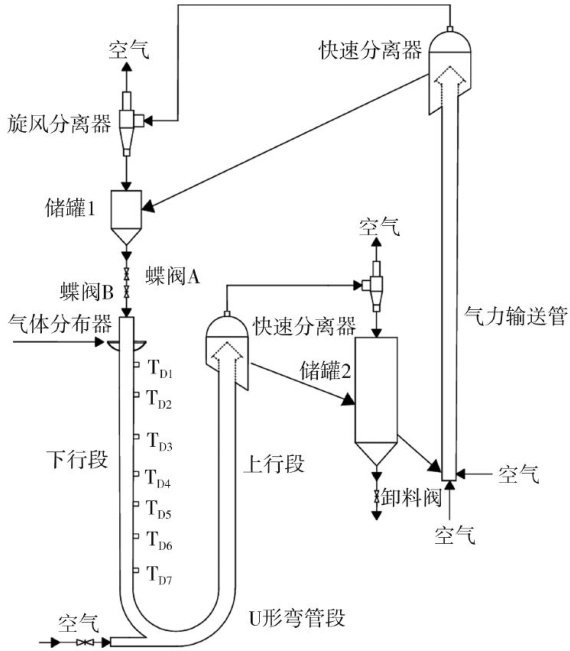

U形管式流化床中下行段颗粒流动特性研究

打开文本图片集

中图分类号:TQ522.5 文献标识码:A DOI:10.7535/hbkd.2025yx06005

Abstract:Toaddressevere pipelinecloggingandwaste waterisuescausedbytarcondensationduringthecolingofrawcoal pyrolysisgas,directcatalyticcrackingofthehotrawgasfromcoalpyrolyzerwasproposedinthisstudytoconvertthepolycyclic compoundsintarintolow-boiling-pointmonocycliccompounds.Furthmore,aU-bendtubularfluidizedbedwasintroducedasthe crackingreactor.Toanalyzethepartile-flowdynamicsinthisreactor,acold-flowmodelexperimentalsetupwasdesignedand constructed.Axialpressureproflesinboththedownersectionandrisersectionsweremeasuredunderrelativelylowbeddensities.The efectsofsolidfuxandsuperfialgasvelocityoeaialanddialdistributisofolidoncentration(theatioftetotalolue of particlestothevolumeofthereactor)andparticlevelocityinthedownersectionwerealsoinvestigated.Theexperimentalresults indicatetattheaxialpresureinthedownersectionincreasesgraduallyfromtotoottom,hiletheoppositetrendoursiteiser section.Inthedownersection,theaxialsolidconcentrationfirstrisesandthenplateaus,exceedingthatinasingledowerunder equivalentconditions.Theaialparticlevelocitydecreasesintediretionofflow.Radially,thesolidconcentrationexhitsa“dense annular”structure,andtheparticlevelocitydeclinesnearthewall.Thisstudyofersfundamentalinsightintotheparticle hydrodynamicsoftheU-bendtubularfluidizedbed,providingreferenceforsubsequentexperimentalresearchandreactorscaleup.

Keywords:multiphase flow reaction engineering;rawgas;fluidized bed;pressre;solid concentration;particle velocity

低阶粉煤分质利用是指通过热解将低阶粉煤转化为焦炭或半焦,同时,将释放的高温荒煤气经冷却和冷凝分离得到焦炉煤气和煤焦油 [1-2] ,最终所有产物均可分别进行高效利用。(剩余11169字)