框架窗口磨削程序的优化研究

打开文本图片集

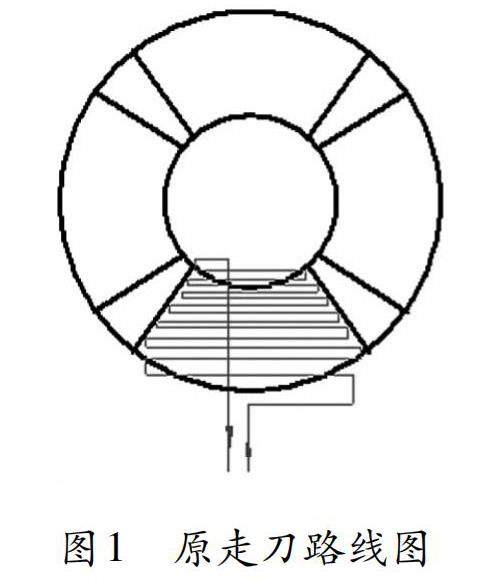

摘 要:框架产品应用于多种行星变速机构产品中,其结构具有复杂化、大型化、薄壁化、精密化等特点。针对扇形框架窗口特殊形状,开展更优的磨削程序研究。文章主要通过优化数控磨床走刀路径,以提高磨削后的表面质量,并有效减少实际运行路径长度,达到提质增效的目的。

关键词:数控磨床程序优化;效率提升

Research on Optimization of Frame Window Grinding Program

Zhao Jing Yang Chengjie

(The Fourth Branch,Inner Mongolia First Machinery Group Co.,Ltd.,Baotou,Inner Mongolia 014030)

Abstract:The frame products are used in many kinds of planetary variable speed mechanism products,and their structure has the characteristics of complexity,large scale,thin wall and precision.For the special shape of fan-frame window,a better grinding procedure is studied.In this paper,the cutting path of CNC grinding machine is optimized to improve the surface quality after grinding,and effectively reduce the length of the actual running path,so as to achieve the purpose of improving quality and efficiency.

Key words:CNC grinding machine program optimization;efficiency improvement

1 项目背景

随着科学技术的迅速发展,框架产品应用于多种行星变速机构产品中,其结构具有复杂化、大型化、薄壁化、精密化等特点。(剩余2228字)