快速成型件段差面品缺陷的解决方案

打开文本图片集

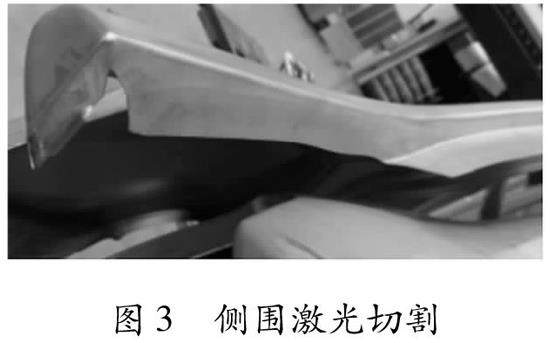

摘 要:汽车侧围零件利用快速成型模拉延成形不充分,后续激光切割时,零件应力释放导致局部型面回弹,最终造成与行李箱盖匹配面差的缺陷问题。本文提供了一种解决面品缺陷的方法,可实现对软模件(快速成型件)减小诱发应力及切割前残余应力,从而减小回弹。关键词:快速成型;面差;回弹Solutions to the Surface Defects of Rapid Prototyping Parts Causedby Segment DiscrepanciesLv Shuyan Liu Xiuqing2Abstract:The automotive side panel parts are not sufficiently formed by stretching using rapid prototyping molds,and during subsequent laser cutting,the release of stress in the parts leads to local surface rebound.This eventually results in a defect in the matching surface with the trunk lid.This paper provides a method to resolve the surface quality defects,which can reduce the induced stress and residual stress in the soft mold parts (rapid prototyping parts) before cutting,thereby minimizing the rebound.Key words:Rapid Prototyping;Surface Discrepancy;Rebound 汽车生产中,一般达到量产的车型全套技术相对比较成熟,生产的产品质量较好,客户满意度也较高。(剩余2094字)