工业废渣-MgO协同固化粉质砂土试验研究

打开文本图片集

中图分类号:TU41 文献标志码:A 文章编号:1672-1098(2025)02-0059-09

引文格式:,,,等.工业废渣- ∇⋅MgO 协同固化粉质砂土试验研究[J].理工大学学报(自然科学版),2025,45(2) :59-67.

DOI:10.3969/j. issn.1672-1098. 2025.02.008

Experimental Study on Industrial Waste Slag-MgO Synergistic Solidification of Silty Sand

WANG Qiang,ZHANG Zhaochang,CHU Zuoyong,GUO Jiawei,LI Yafeng (Schol of CivilEngineringandArchitecture,Anhui UniversityofScienceandTechnology,HuainanAnhui32Ool,China)

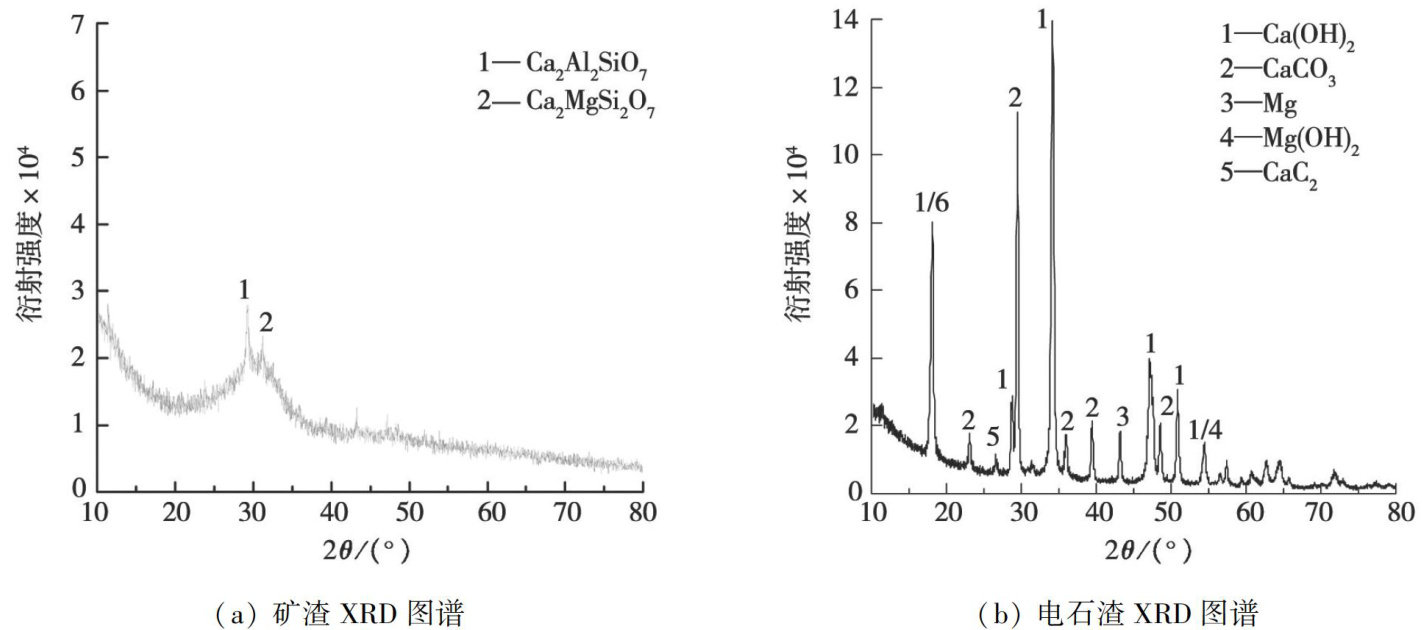

Abstract:Objective To address environmental pollution from industrial waste and improve silty sand for subgrade filling,slag,calcium carbide slagand MgO were employed to solidify silty sand.Methods Unconfined strength (UCS), X- ray diffraction (XRD),and electron microscope scanning (SEM) tests were carried out to evaluate the effcts of curing agent ratios and curing ages on soil strength and microstructure.Results The Orthogonal tests on 40% moisture-content silty sand showed that slag dominated UCS at 7d and 56d ( slag>MgO> calcium carbide slag),while calcium carbide slag surpassed MgO at 14d and 28d (slag > calcium carbide slag > MgO) . The optimal ratio was 15% slag +7% calcium carbide slag +8% (204号 MgO . The greatest effect of slag on the strength of the specimen was found at 7d,14d and 56d. The optimum ratio of the curing agent was 15%slag+7% calcium carbide slag +8% (20 MgO . Peak stress failure strains ranged from 0.9% to 1.9% ,inversely related to peak stress. Microstructural analysis showed that hydration products (C-S-H and M-S-H )filled pores and bonded particles, enhancing strength. Conclusion The research supports green,low-carbon slag-calcium carbide slag-Mg0 binders for soil stabilization.

Key words : silty sand solidification ;slag;unconfined compressive strength; microscopic properties

我国地域广阔,路基土分类繁多,一些特殊土如黄土、膨胀土等工程性能差,用作路基材料时承载力不足。(剩余15128字)