城市轨道交通单护盾TBM刀盘掘进数值模拟

打开文本图片集

中图分类号:U455.3 文献标志码:A 文章编号:2097-3853(2025)03-0245-09

Abstract:Based on the measured data of Fuzhou Binhai Expressway,the finite element software was used to numerically simulate the cutterhead excavation.The force analysis of the cutterhead was carried out under different excavation speeds and torques.Analysis shows that the harder the rock,the lower the excavation speed of the cuterhead,and the higher the torque and rotation speed of the cutterhead;as the pole diameter increases,the average stressvalue of the cuter shaft gradually increases,and the average stress of the cuter head increases first and then decreases.The cutter shaft and the middle position of the cuter head with larger pole diameters are prone to damage;during the initial stage of thecuterhead,it is susceptible to impact loads,resulting in high stress values. Subsequently,the stress gradually decreases and eventually stabilizes.

Keywords: TBM tunnel; cuttrhead breaking rock;excavation speed; cutterhead torque; finite elementanalysis

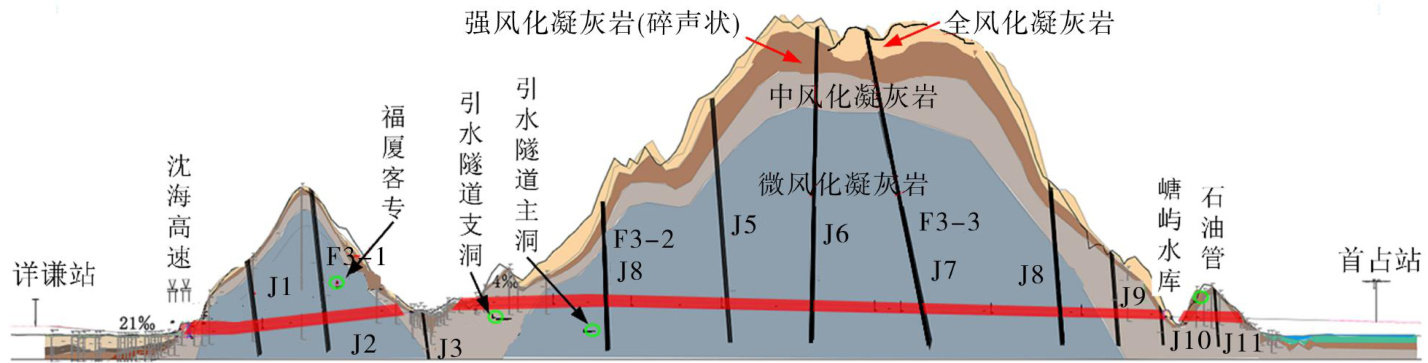

盾构掘进过程中通过刀轴将岩石的反作用力传递给刀盘,使刀盘在掘进过程中承受多点强冲击破岩载荷,且盾构在中、微风化凝灰岩、局部洞口风化层及洞身破碎带为强风化凝灰岩地带,容易发生设备卡机栽头、管片错台等风险事件,因此,有必要对该类地质下刀盘受力进行数值模拟分析[1],为类似工程提供理论依据

国内外专家针对刀盘破岩的受力及数值模拟进行了一系列研究,Cui等[2]分析了两个不同地层隧道掘进关键参数的差异,建立的三维有限差分模型在精度和效率方面具有较好的性能。(剩余8344字)