数据驱动的光电模块生产过程优化及改善

打开文本图片集

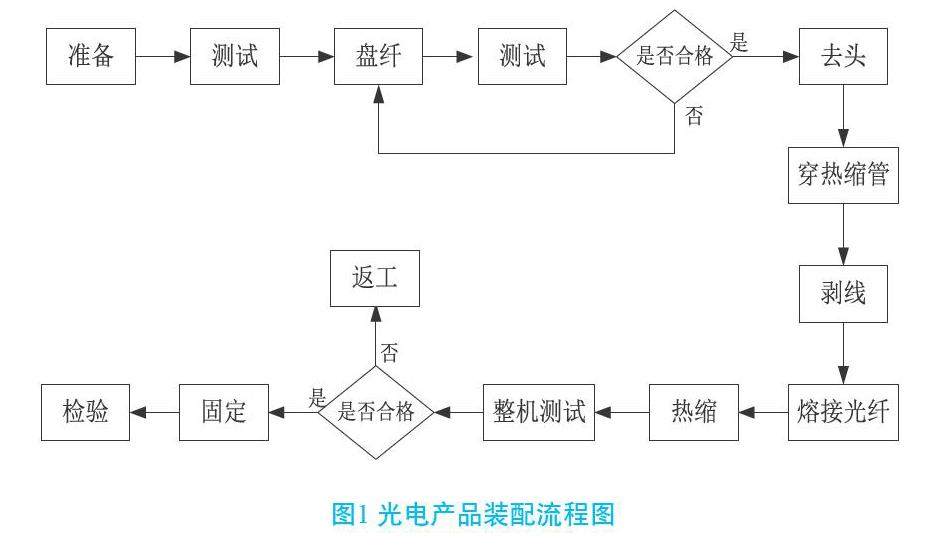

摘要:文章利用光电模块生产数据,基于贝叶斯网络分析识别光模块生产过程的瓶颈环节,为光纤盘纤和光纤熔接中的光纤切割环节提供支持。最后,结合光电模块生产特点及现状,提出相应改进措施,优化及改善光电模块的生产过程,应用效果显示,该识别方法及改善措施有效且经济。

关键词:光纤盘绕;光纤熔接;传输损耗

doi:10.3969/J.ISSN.1672-7274.2023.04.048

中图分类号:TN 913.7 文献标示码:A 文章编码:1672-7274(2023)04-0-04

Data Driven Production Process Optimization and Improvement of Photoelectric Module

YANG Junli, LI Yuehua, TANG Luzhen

(The 29th Research Institute of China Electronics Technology Group Corporation, Chengdu 610036, China)

Abstract: In this paper, the bottleneck of optical module production process is identified based on Bayesian network analysis using photoelectric module production data. The bottleneck link is identified and analyzed as fiber disc fiber and fiber cutting link in fiber welding. Finally, combined with the characteristics and current situation of photoelectric module production, the corresponding improvement measures are proposed to optimize and improve the production process of photoelectric module. The application results show that the identification method and improvement measures in this paper are effective and economical.

Key words: optical fiber coiling; optical fiber welding; transmission loss

1 研究背景

与传统的射频电缆相比,光纤传输具有传输频带宽、通信容量大、传输损耗小、不受电磁干扰、保密性好、直径小、质量轻的优点,能够有效解决射频电缆保相传输能力差,传输损耗大,体积质量大、抗电磁干扰能力弱的缺陷。(剩余4080字)