采用SHAP的高压涡轮级高维设计空间数据挖掘

打开文本图片集

关键词:高压涡轮级;高维设计空间;数据挖掘;SHAP方法中图分类号:TK471文献标志码:ADOI:10.7652/xjtuxb202506015 文章编号:0253-987X(2025)06-0144-11

Data Mining for High-Dimensional Design Space of High Pressure Turbine Stage Using SHAP

YANG Zhaol,GUO Zhendong1 ,SU Pengfei²,WANG Qinengl ,SONG Limingl (1.School of Energy and Power Engineering,Xi'an Jiaotong University,Xi'an 710049,China; 2.State Key Laboratory of Clean and Efficient Turbomachinery Power Equipment, Dongfang Turbine Co.,Ltd.,Deyang,Sichuan 618ooo,China)

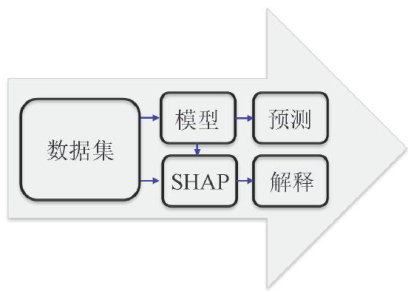

Abstract: In order to clarify the influence of various variables on the performance of turbine stage in high-dimensional design space,the knowledge mining of 93 design variables of GE-E3 highpressure turbine first stage was carried out based on the data mining method SHAP. In addition to the analysis of the influence of significant variables on the overall performance in conventional data mining work,the analysis method of the influence of significant variables on the performance distribution along spanwise of turbine stages was developed,and the specific positions of turbine stage affected by the design variables to improve the overall performance of the stage were visualized.At the same time, SHAP's advantage in local explanations was fully leveraged,attribution analysis on typical samples in the design space was conducted,and the role of each design variable in the change of performance indicators was studied. The results showed that for the high-pressure turbine stage,significant variables affecting stage efficiency included the effective output angle, three-dimensional stacking parameters of the stator,and the spline control points near the suction leading edge of blades. Based on GE-E3 high-pressure turbine dataset,data mining was conducted to obtain turbine stage design criteria: When the effective output angle of the middle section of the rotor is reduced and the effective output angle of the middle section of the stator is increased, the circumferential top and middle positions of the three-dimensional stack points of the stator will be shifted to the pressure surface,and the control points near the suction leading edge of the middle section of both the stator and rotor will move in the direction of blade thinning. The new design according to the design criteria has improved the stage efficiency by 0.65%

Keywords: high-pressure turbine stage; high-dimensional design space; data mining; SHAPmethod

涡轮的气动设计一直是国内外学者研究的重点。(剩余16113字)