β-磷酸钙增强锌合金激光选区 熔化成型与界面调控

打开文本图片集

中图分类号:TG146 文献标志码:A

DOI: 10.7652/xjtuxb202506008 文章编号:0253-987X(2025)06-0073-09

Selective Laser Melting Molding and Interface Control β -Tricalcium Phosphate-Enhanced Zinc Alloys

ZHANG Xuanming,SUN Kun, ZHANG Liang,FU Yulong, YANG Longlong,LIU Xiao,ZHANG Yubao (,China)

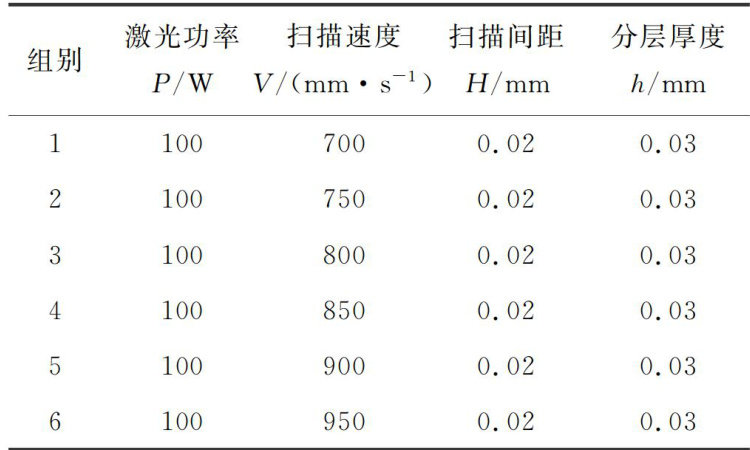

Abstract: Aiming to address the issue poor degradation and osteogenic properties traditional metal bone implants,a method preparing zinc alloy bone implants with both excellent mechanical properties and osteogenic permance is proposed. Firstly,a mechanical mixing method was used to prepare a unim mixture zinc,magnesium,and β -tricalcium phosphate powders. Then, selective laser melting technology was employed to fabricate β -tricalcium phosphate-reinced zinc alloy,and the optimal process parameters were obtained. Finally,by coating the surface β -tricalcium phosphate with nano ,the interface control the composite material was carried out to enhance its mechanical properties. The results showed that the optimal scanning speed was 800mm⋅s-1 . The fabricated composite material had a fine microstructure,with a density reaching 99.7% ,a microhardness 168.66,and a compressive strength 517.34MPa . After interface control, the microhardness and compressive strength the composite material were approximately 183.96 and 602.65MPa ,respectively,which are 9% and 16% higher than those the original composite material. Theree,the interfacial bonding strength and the overall mechanical properties the composite material have been enhanced. The study proves that the zinc,magnesium,and β -tricalcium phosphate composite material fabricated by selective laser melting technology is a promising bone implant material, laying the foundation the preparation zinc alloy skeletal implants.

words: selective laser melting; bone implants; zinc alloy; β -tricalcium phosphate;interface control

激光选区熔化技术(SLM)是基于离散-堆积原理,根据计算机辅助设计(CAD)数据,利用高强度激光作为能量来源,按规划路径逐层熔融金属粉末的过程,特别适合人体骨骼修复体的个性化制造[]。(剩余13170字)