基于激光超声的阀门焊接缺陷检测有限元仿真

打开文本图片集

中图分类号:TP2 文献标志码:A

文章编号:2096-2983(2025)04-0082-08

引文格式:,,,等.基于激光超声的阀门焊接缺陷检测有限元仿真[J].有色金属材料与工程,2025,46(4):82- 89.DOI: 10.13258/j.cnki.nmme.20241127001.FANG Zhongshu, XING Zhili,LIJinyong,etal.Finiteelement simulationof valve weldingdefectdetectiondasedonlaserultrasound[J].NonferousMetalMaterialsandEnginering,2025,46(4):82-89.

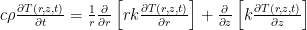

Abstract: In this paper, the interaction mechanism between laser ultrasonic absorption and valve welding defects is studied,and the physical process of pulsed laser-excited ultrasonic waves is numerically simulated based on COMSOL software, and the propagation characteristics and laws of laser-excited ultrasonic waves in the valve material are systematically explored. By establishing two types of valve welding models,the temperature field, stressfield and pressure field excited by the laser on the valve surface were simulated,the change law of the three physical fields was studied, and the echo signals of the two models were compared and verified,and the position of the welding defect was obtained by analyzing the echo defect information through numerical simulation, the specific position of the welding defect is inversely obtained. The results show that the defect position and shape obtained by simulation are highly consistent with the preset parameters of the model. This study verifies the feasibility and accuracy of laser ultrasonic technology for valve defect detection, and confirms that the ultrasonic waves of various modes excited by laser can be used as an effective method for accurately detecting valve welding defects in industrial scenarios.

Keywords: laser ultrasound; finite element analysis; COMSOL software; valve welding defects

在工业生产领域,阀门作为流体控制系统中不可或缺的关键组成部分,其质量的优劣直接关系到工业生产的安全性[1-2]。(剩余6904字)