SCR法连铸连轧工艺与铸坯缺陷的研究现状

打开文本图片集

中图分类号:TG290 文献标志码:A

文章编号:2096-2983(2025)04-0068-08

引文格式:,,,等.SCR法连铸连轧工艺与铸坏缺陷的研究现状[J].有色金属材料与工,2025,46(4):68-75. DOI: 10.13258/j.cnki.nmme.2024042001.LIANG Haicheng, GU Liyao, CHENG Ming,et al.Research status of SCR continuous casting and rolling processand casting billt defects[J].Nonferrous Metal Materials and Engineering2025, 46(4) : 68-75.

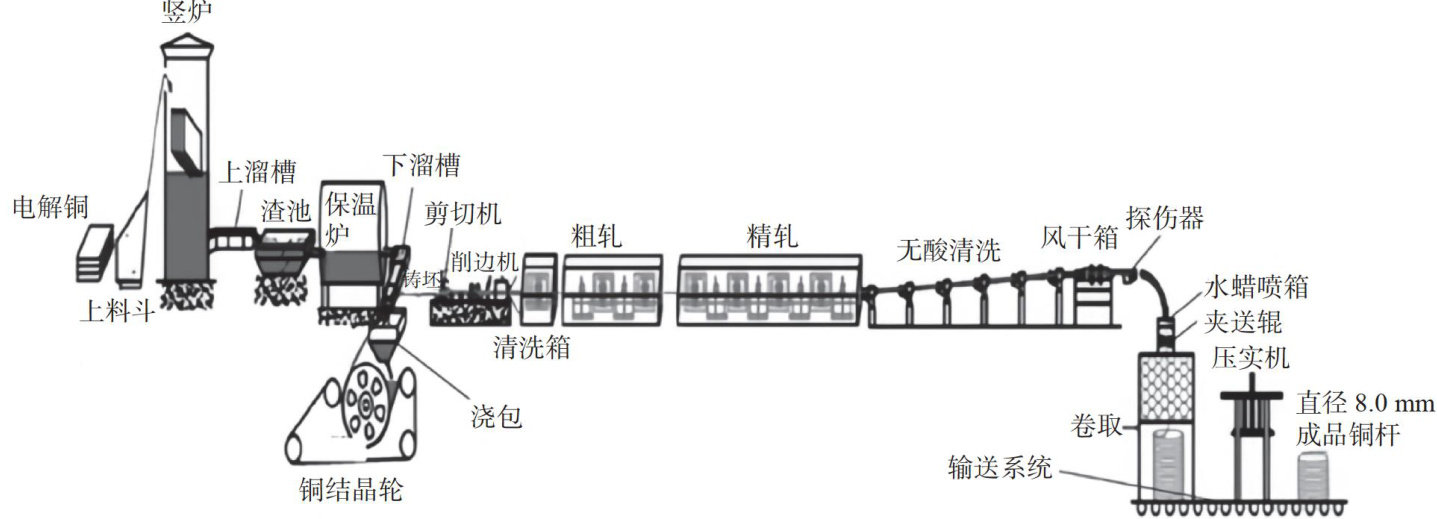

Abstract: With the rapid development of the electronics industry, the demand for copper rod in China has been continuously increasing. At present, the submerged continuous rheocasting (SCR) continuous casting and rolling process is the main technology for copper rod production. Combined with the on-site SCR7000 bright copper rod continuous casting and roling production line, this paper systematically introduces the SCR continuous casting and rolling equipment, the SCR continuous casting and rolling production process flow,the basic structure of the five-wheel casting system,and the core advantages of the SCR continuous casting and rolling process. It then focuses on the defect issues in the production process,comprehensively summarizes the formation mechanisms of four typical defects in cast billts—porosity, inclusions, shrinkage cavities,and cracks—and proposes corresponding improvement measures to enhance cast billet quality. Through the aforementioned improvements, defects have been effectively prevented and the yield rate has been significantly improved. Finally, the future development trend of SCR continuous casting and rolling production in China is prospected.

Keywords: SCR continuous casting and roling; five-wheel continuous casting system; preparation process; defects of casting billet

浸没式连续流变铸造(submergedcontinuousrheocasting,SCR)连铸连轧法,是一种将连铸与连轧工艺深度融合的先进生产技术。(剩余9817字)