超超临界机组HR3C再热器受热面管组织、性能及持久寿命分析

打开文本图片集

文章编号:2096-2983(2025)03-0086-07

关键词:HR3C钢;显微组织;性能;持久寿命中图分类号:TG142.73 文献标志码:A

Abstract: HR3C,an optimized variant of TP31O austenitic heat-resistant steel, is widely used in supercritical units and ultra-supercritical units because of its good high temperature mechanical properties and high temperature oxidation resistance.The HR3C heating surface tube at the outlet from the final reheater in an ultra-supercritical unit of a power plant with accumulated service of about 60000h (204号 has been taken as the research object. The microstructures and properties as well as creep rupture life were investigated by Brinell hardness tests, tensile tests, metallographic examination, scanning electron microscope and transmission electron microscope observations, and high temperature lasting strength test.The results show that, compared with the as-received state,the amount of precipitated phases in the microstructure of the HR3C heating surface tube after service increases significantly; the Brinell hardnes,the tensile strength and the yield strength all increased,while the plasticity significantly decreases during tensile tests at room temperature,but remains relatively high during tensile tests at high temperatures. Based on the results of the high temperature lasting strength test, the remaining life of the heating surface tube under the service condition of 650∘C is calculated to be greater than 100000h

Keywords: HR3C steel; microstructure; properties; creep rupture life

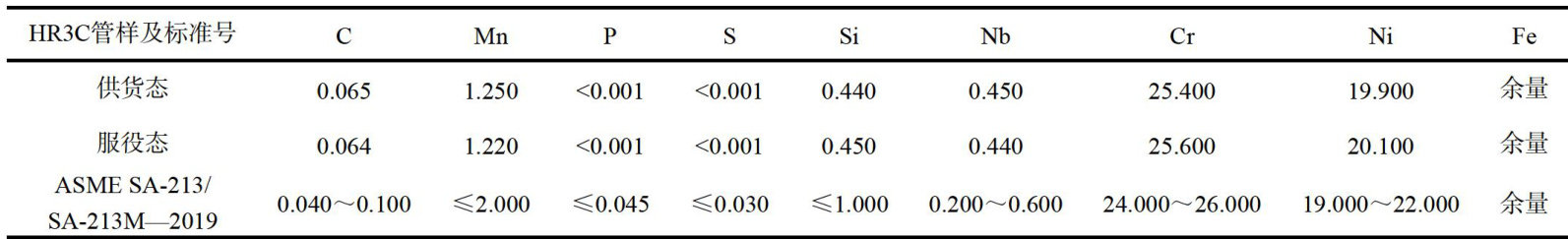

超超临界(ultra-supercritical,USC)机组由于具有能源利用率高、排放污染物少等优点,是目前火电机组主要的发展方向[1]。(剩余7341字)