基于遗传算法的被动式木窗材下料优化

打开文本图片集

中图分类号:S777 文献标识码:A DOI:10.7525/j.issn.1006-8023.2025.03.016

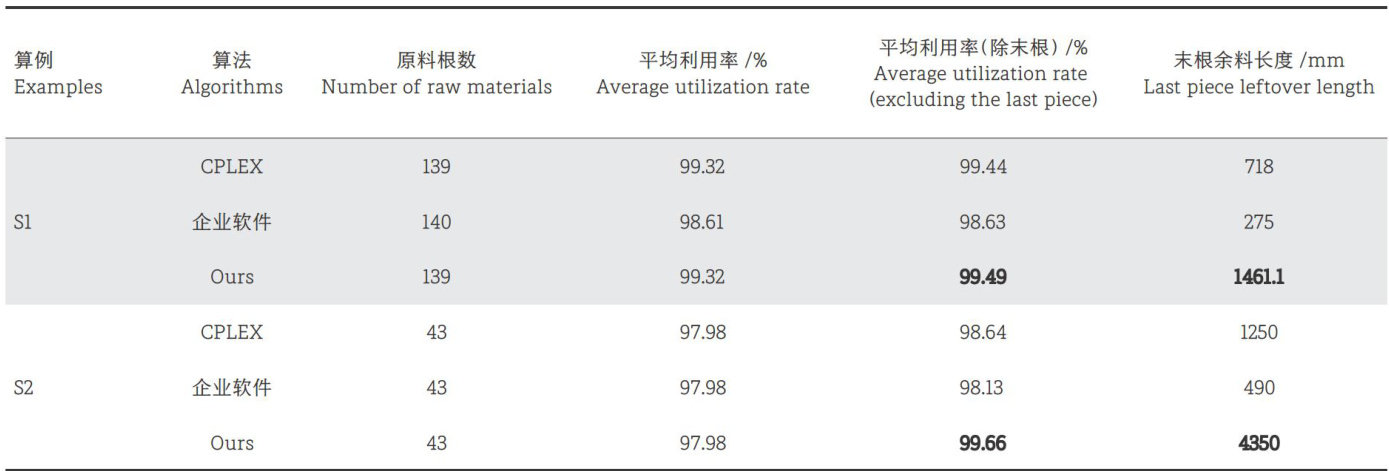

Abstract:In thecustomization process of pasive wooden window manufacturing,reducing material wasteduring frame cutting is keytocostreduction.This problem is modeledasaone-dimensional cutting stock problem.Toadress the issue of traditional geneticalgorithms wheretheindividual encoding method tends toleadtothedestructionofcuing patternsandlow exploration eficiency during iterations,anew individual encoding methodis proposed to maintainthe integrityofcutting patterns throughout the evolutionary process.Additionally,aheuristic strategy andacorrection strategy are introduced for individual correctionandpopulationevolution.Simulationresultsshowthat fordiferent testcases, the average material utilization rate,excluding the last remnants,exceeds 99 % ,with some improvements in the length of thelastremnants compared toother algorithms.Fortwosets ofreal production data fromenterprises,the proposed algorithmachieves the theoreticallower bound,withaverageutilizationrates (excluding the lastremnants)of 99.49%and 99.66%,respectively,outperforming the resultsofthe company's existing software.This demonstrates the algorithm's potential to efectively reduce costs and provide practical solutions in engineering applications.

Keywords:One-dimensionalcutting stock problem;genetic algorithm;heuristic algorithm;population encoding;usable leftovers

0 引言

场正在不断扩大。(剩余9846字)