两种材料旋翼轴低周疲劳试验分析

打开文本图片集

摘 要:在不改变结构尺寸的情况下,为验证钛合金TC18是否可以替代传统材料15-5PH应用于直升机旋翼轴,该文对2种材料的旋翼轴进行试验对比分析,结果表明TC18材料的旋翼轴低周疲劳寿命较低。因此当选材为TC18时,需优化结构特征,提升疲劳寿命裕度,才能满足寿命要求。

关键词:旋翼轴;TC18;15-5PH;疲劳寿命;钛合金

中图分类号:V275.1 文献标志码:A 文章编号:2095-2945(2023)19-0071-04

Abstract: In order to verify whether titanium alloy TC18 can replace the traditional material 15-5PH to be used in helicopter rotor shaft without changing the structure size, the rotor shafts of the two materials are tested and compared in this paper. the results show that the low cycle fatigue life of TC18 material is low. Therefore, when TC18 is used, it is necessary to optimize the structural characteristics and improve the fatigue life margin in order to meet the life requirements.

Keywords: rotor shaft; TC18; 15-5PH; fatigue life; titanium alloy

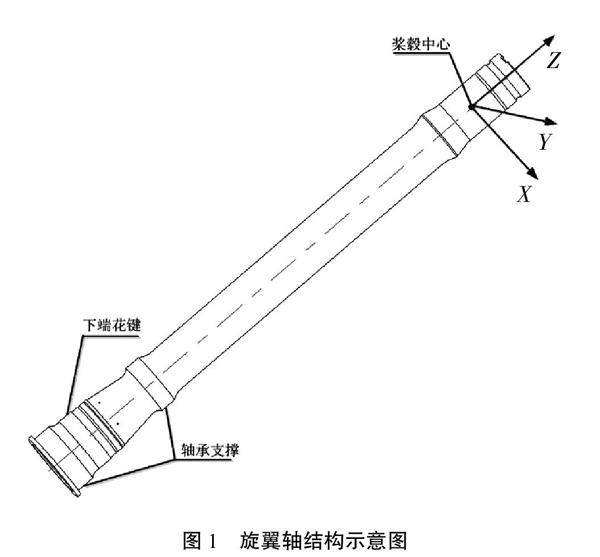

旋翼轴是直升机动力装置最关键的零件之一,其连接主减速器和旋翼,传递旋翼升力和功率,其工作的可靠性直接影响飞机的安全[1]。(剩余4228字)