淬火冷却介质对40CrNiMo钢矿用链轮轴调质后组织与力学性能的影响

打开文本图片集

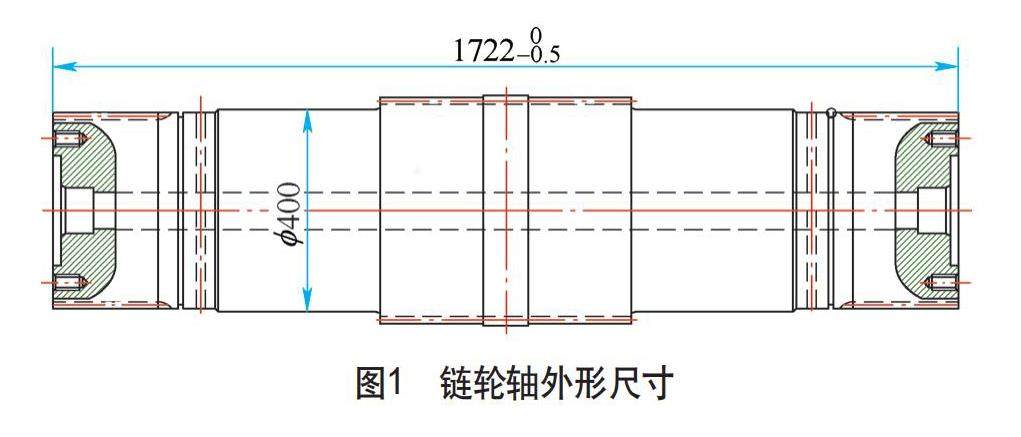

摘要:采用力学性能测试及显微组织观察等手段,研究淬火介质对40CrNiMo钢矿用链轮轴调质后组织与力学性能的影响,发现油淬后回火样品的金相组织为致密、均匀的回火索氏体,具有较高的强硬度和较好的塑韧性。研究结果可为矿用链轮轴热处理工艺设计提供理论依据,对指导实际生产具有参考价值。

关键词:40CrNiMo钢;矿用链轮轴;淬火冷却介质;力学性能

Quenching and cooling medium on the structure of 40CrNiMo steel mining sprocket shafts after quenching and tempering the impact on mechanical properties

SU Zhenning1, 2, MA Kun1, 2, WANG Zhiying1, 2

1. Middling Coal Zhangjiakou Coal Mining Machinery Co., Ltd., Zhangjiakou 076025, Hebei, China

2. Hebei Province High End Intelligent Mining Equipment Technology Innovation Center, Zhangjiakou 076025, Hebei, China

Abstract: By using mechanical property testing and microstructure observation, the effect of quenching medium on the microstructure and mechanical properties of 40CrNiMo steel mining sprocket shaft after quenching and tempering was studied. It was found that the metallographic structure of the tempered sample after oil quenching was dense and uniform tempered martensite, with high strength, hardness, and good plasticity and toughness. The research results can provide theoretical basis for the design of heat treatment process for mining sprocket shafts and have reference value for guiding actual production.

Keywords: 40CrNiMo steel; mining sprocket shaft; quenching cooling medium; mechanical property

1 序言

刮板输送机是煤矿井下综采工作面中的输送设备,主要作用是将采煤机采下的煤炭连续不断地运出工作面。(剩余5932字)