压力机拆垛站生产节拍的提升改造

打开文本图片集

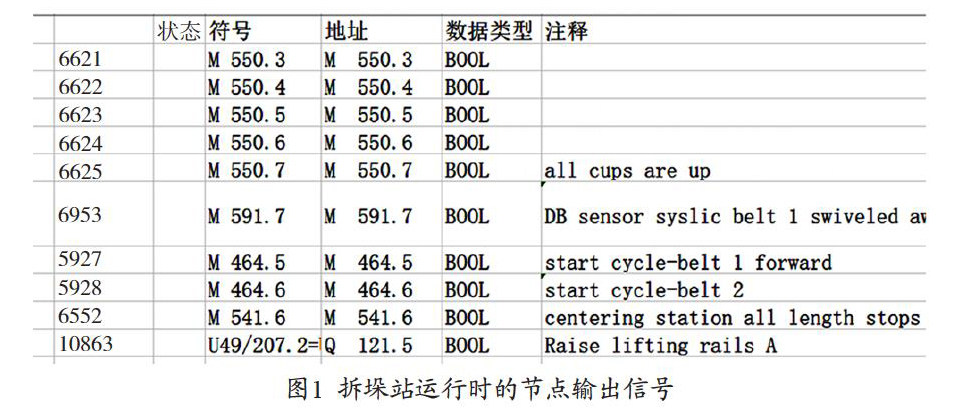

[摘 要]米勒·万家顿2 400 t压力机自动生产线在生产节拍为SPM12时,拆垛站偶发每分钟只送11张板料,造成整线损失了一个节拍,压机出现了“空压”异常现象。针对该现状进行真空气缸改造升级,提高拆垛站送料速度,使压机整线生产节拍达到SPM12值。

[关键词]拆垛站;节拍损失;破真空装置

[中图分类号]TG385.9 [文献标志码]A [文章编号]2095–6487(2021)04–00–02

Improvement of the Production Cycle of the Destacking Station of the Press

Wu Zhen-tong

[Abstract]When the automatic production line of Miller Weingarten 2400 T press is at SPM12, the destacking station occasionally delivers only 11 sheets per minute, causing the entire line to lose one beat, and the press has an "air pressure" abnormality. phenomenon. According to the current situation, the vacuum cylinder was upgraded and upgraded, and the feeding speed of the destacking station was increased, so that the production cycle of the entire press line reached the SPM12 value.

[Keywords]destacking station;beat loss;vacuum breaking device

拆垛站送料裝置为冲压线分张提供钢制板料,它既可以为冲压线提供单片板料也可以提供双片板料,通过拆垛工位下部的升降台,举升架将料垛举升到板料吸着区,所预选的真空气缸拾取料垛最上面的板料,并将其运送到磁性皮带上,磁性皮带将板料输送给清洗机内进行清洗,清洗机清洗完成后输送到对中台定位,上料机械手从对中站处吸取板料并将其送入打头压机模具内,模具将板料冲压成形。(剩余1746字)

网站仅支持在线阅读(不支持PDF下载),如需保存文章,可以选择【打印】保存。