新型自振动PDC钻头研制与应用

打开文本图片集

Development and Application of A New Self-vibration PDC Bit

YAO Jianlin1,QIAO Huotong1,LIU Ke1 ,HUANG Wei²*,LIU Bin1

1.CNPC Chuanqing Drilling Engineering CompanyLimited, Guanghan,Sichuan 6l83oo,China 2.SichuanChuanqing Petroleum Drilingand Production TechnologyCompanyLimited,Guanghan,Sichuan 61830,China

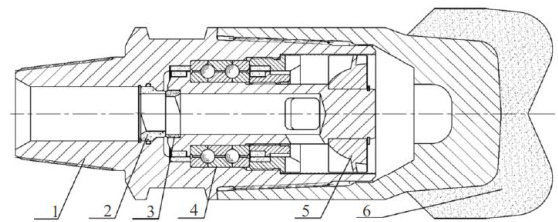

Abstract: Duetothe problemsofseriousback-pressre,large frictionandtorque fluctuationinthedrilingofbuild-upsection andhorizontalsection,therock breaking WOBcannotbeefectivelyapplied,which resultsresulting inlowROPof conventional PDC bitrun.Byusing toolssuchas hydraulicagitator,compoundbit,certainefectonaccelerationofROPcanotbe achieved,butlsteriingesaotfullytuetoliitatioofoolize,istalltionposioandowoley ofcompoundbit.Therefore,aself-vibrationunitofcompact structure is designed basedon the principleof water hammer impact.A new ϕ215.9mm self-vibration PDC bit is developed.Through theoretical calculation and CFD numerical simulation technology combined with key parameters such as vibration frequency and vibration force, a new ϕ215.9 mm self-vibration PDCbit isdeveloped,whichcan produce low-frequencyaxial impactforcedirectlyacting onrock.Thefieldapplication in well Yun′anX1 shows that the mutation frequency and variation range of the hook load of the new self-vibration PDC bit are significantlylowerthanthoseoftecompoundbitinthesamesectionofthesamewell,whicheffectivelyreducesthefriction betweenthe driltringand theboreholewallandfurtherallviates thebackpressure problem.Thus,theaverageROP is increased by 32.97% in the same well compared to that of compound bit, and by 74.50% compared to that of the conventional PDC bit in the adjacent well,realizing the speed increase,cost reduction and efficiency increase.

Keywords:PDC bit;build-up section;horizontal section;back pressure; self-vibration

引言

随着油气勘探开发的不断深入,定向井技术已成为石油勘探开发领域最常用的钻井技术之一,其中,长水平段水平井能够增加泄流面积,有效提高单井产量,改善油气藏开发效果,已经成为国内外低渗透、致密油气和页岩油气等非常规油气资源规模效益开发的重要技术之一[1-3]。(剩余18231字)