回采巷道非对称底鼓机制与切槽卸压控制技术

打开文本图片集

中图分类号:TD353 文献标志码:A

Abstract: In mining roadways located between solid coal and smallcoal pilas,the problem of asymmetric floorheave is severe due to the influence offactors such as asymmetric support pressure,plastic deformationof small coalpillars,and weak floor strata.Traditional supporttechnologiesaredifficult toeffectivelycontrol this issue.Toaddress this issue,acombinationof theoretical analysis,numerical simulation,and field testing was employed toanalyze thestress distribution characteristicsandreveal the formation mechanismof asymmetric floor heave.A groovecuting pressure relief control technology was proposed,in which grooves ofspecific depth and width were cut into the roadway floor to transfer high shallow stress to the deep rock mass outside the pressure relief groove,while also providing deformation space for the shallow surrounding rock.This reduced stressconcentrationand theaccumulation of deformationenergy,thereby effectively suppressing floor heave. Theoretical calculations indicated that the maximum failure depth of the roadway floor was 2.04m, and numerical simulations were used to determine the optimal parameters for field groove cutting.Industrial-scale field test results showed that the floor heave amount in the groove cutting pressure relief site was reduced by 94.99% (204号 compared to the non-grooved site, verifying that groove cuting pressure relief can effectively resolve the problem of floor heave in practice.

Key words: mining roadway; asymmetric floor heave; groove cuting pressure relief; stress distribution; groove parameter optimization

0引言

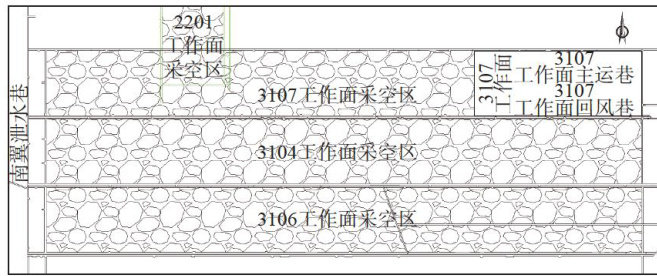

1工程背景

在煤炭资源开采过程中,回采巷道是井下运输通风及行人的关键通道[1-2]。(剩余14107字)