立井提升系统刚性罐道故障诊断方法

打开文本图片集

中图分类号:TD53/67 文献标志码:A

Fault diagnosis method for rigid guides in vertical shaft hoisting systems

WANGJianfeng1,JINYuanzhi²,ZHANGYong²,WANGYongzhen³,HE Jiacong³ (1.Shandong Province Sanhekou Mining Co.,Ltd.,Zaozhuang 277605,China;2.Zaozhuang Mining Group Gaozhuang CoalMiningCo.,Ltd.,Zaozhuang2776o5,China;3.SchoolofMechanicalandElectrical Engineering, ChinaUniversity ofMiningand Technology,Xuzhou , China)

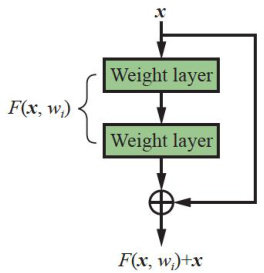

Abstract:Rigid guide is a keycomponent of vertical shaft hoisting systems.Due to shaft deformation and steel corrosion,faultsare likely tooccur,affectingthenormal operationof thecage.Atpresent,vibration detectionmethodsaremostlyused forrigid guidefaultdiagnosis,butthediagnosticaccuracyiseasilyaffected by operating conditions such ascage load and rumning speed.Toaddressthis problem,eddy current sensors are used to collct fault signals of the rigid guides,ensuring thatthe signalfeatures arenot affected bythecage's operating environment.To improve the accuracy of rigid guide fault identification,Residual Attntion One-Dimensional Convolutional Neural Network (RAlDCNN) was proposed.The network extracted multi-scale features through paralel multi-scale convolutions,enhancing itsability to perceive signal features at diferent scales.Channel attention and spatial attention modules were introduced and combined with the residual learning mechanism to design aresidual atention module,which simultaneously captured channel and spatial feature information, extracting more discriminativefeatures.Anexperimental platformforrigid guide faultswas established to simulate diferent types and severities of rigid guide faults. Ablation experiments and comparative experiments were conducted on RA1DCNN. The results showed that the RA1DCNN achieved 100% accuracy in identifying rigid guide fault categories, an average accuracy of 99.7% in identifying the severity of clearance faults, and an average accuracy of 97.68% in identifying the severity of misalignment faults, verifying the effectiveness of the multi-scale convolution layers and residual attention module.The overall fault identification accuracy reached 98.05% , outperforming comparative models including one-dimensional convolutional neural networks.

Key words: vertical shaft hoisting system; rigid guides; guide fault diagnosis; eddy current detection; onedimensional convolutional neural network; multi-scale convolution; residual learning; atention module

0 引言

立井是地下矿井的重要组成部分,主要用于运输人员、设备和材料。(剩余16305字)