中金1680m3 高炉上料筛分工艺的应用和探讨

打开文本图片集

摘 要:高炉原燃料含粉率高对高炉冶炼影响大,造成高炉炉况波动,气流分布混乱,不利于中心气流形成。因此降低入炉的含粉量,使高炉炉况正常便于操作,是保证高炉稳定运行,顺产高产的一项重要措施,从而达到降本增效,实现较大的经济效益。

关键词:高炉;生产;工艺;筛分;应用

APPLICATION AND DISCUSSION OF ZHONGJIN

1 680 m3 BLAST FURNACE

Xie Cong Chen Jiexiang Gan Xing Zhang Langming Liang Hui

(Guangxi Liugang Zhongjin Stainless Steel Co., Ltd. Yulin 537624,China)

Abstract:The high powder content of blast furnace raw fuel has a great influence on blast furnace smelting, resulting in the fluctuation of blast furnace condition and chaotic airflow distribution, which is not conducive to the formation of central air flow. Therefore, reducing the powder content into the furnace, making the blast furnace condition normal and easy to operate, is an important measure to ensure the stable operation of the blast furnace and high yield, so as to achieve cost reduction and efficiency, and achieve greater economic benefits.

Key words: blast furnace;manufacture;technics;screening;apply

1 概 述

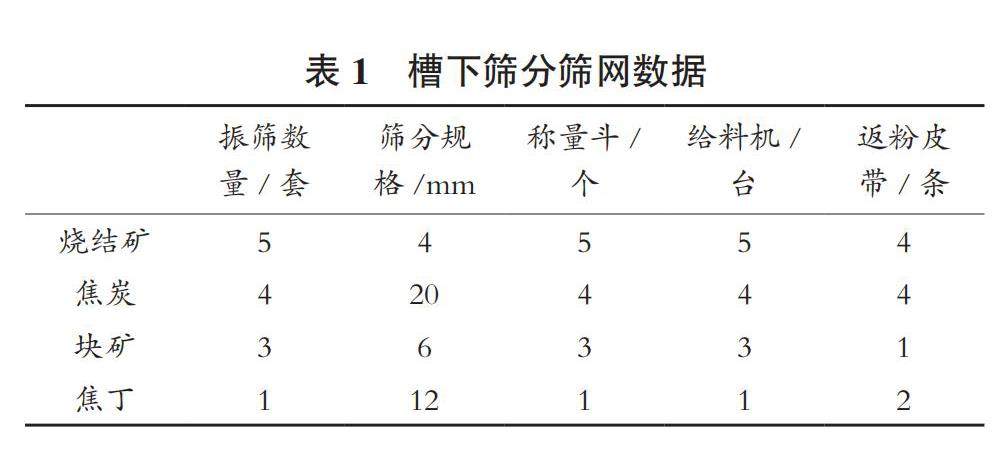

目前中金1 680 m3高炉用于冶炼的原燃料主要有焦炭,烧结矿,块矿。(剩余2337字)