焦炉循环烟气加热技术控制氮氧化物生成的研究与实践

打开文本图片集

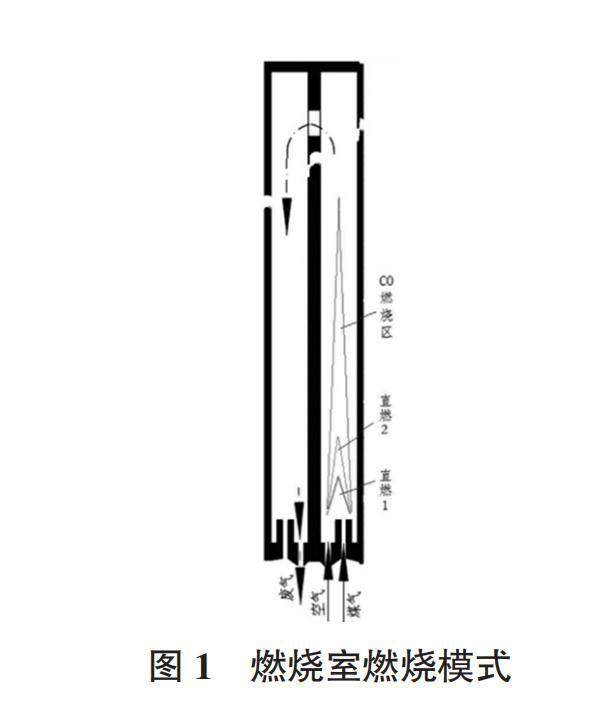

摘 要:阐述循环烟气加热技术在焦炉生产过程中改变了燃烧机理,使焦炉燃烧室垂直温度分布均匀,降低焦炉生产标准温度,从而控制氮氧化物的生成,分析循环烟气燃烧模式变化带来的节能减排效果;介绍将该技术应用于焦化生产实践所增加的工艺控制点、设备配置情况及其产生的效果。

关键词:循环烟气加热;垂直温度分布;低氮燃烧;超低排放

RESEARCH AND PRACTICE ON CONTROLLING NITROGEN OXIDE GENERATION USING COKE OVEN CIRCULATING FLUE GAS HEATING TECHNOLOGY

Wang Ming Yang Zhiwei Liu Yanqi

(Fangda Special Steel Technology Co., Ltd. Nanchang 330012)

Abstract:The article explains that the circulating flue gas heating technology has changed the combustion mechanism in the coke oven production process, making the vertical temperature distribution of the coke oven combustion chamber uniform, reducing the standard temperature of coke oven production, thereby controlling the generation of nitrogen oxides, and analyzing the energy-saving and emission reduction effects brought about by the changes in the circulating flue gas combustion mode. This article introduces the process control points, equipment configuration, and the resulting effects of applying this technology to coking production practice.

Key words: circulating flue gas heating;vertical temperature distribution;low nitrogen combustion;ultra-low emissions

0 前 言

焦化厂在生产过程中需要在燃烧室燃烧煤气对碳化室提供热量,将原煤进行干馏产生焦炭,同时排放燃烧室产生的废气。(剩余4811字)