提高中厚板淬火炉出炉温度命中率的实践研究

打开文本图片集

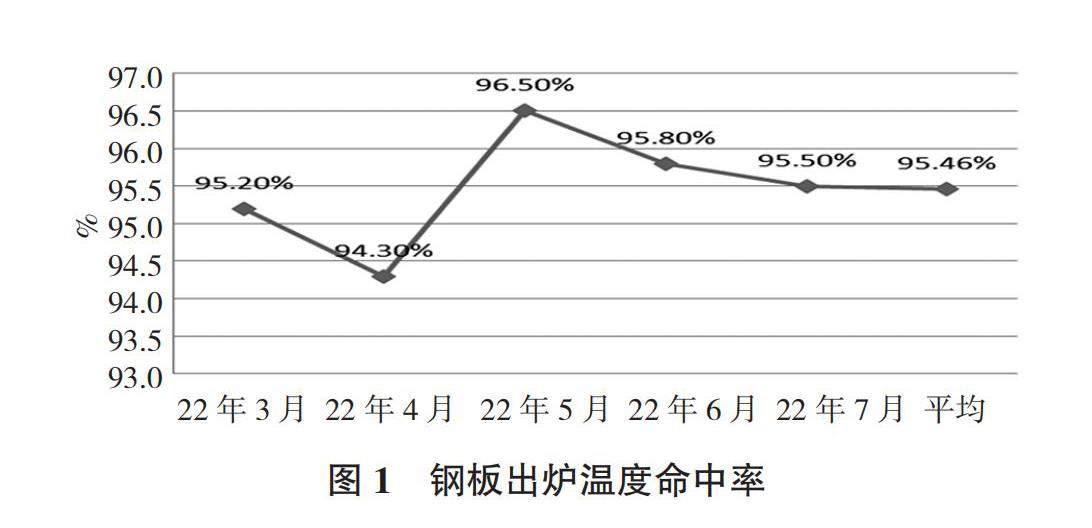

摘 要:某公司淬火炉因燃气种类变化对燃烧系统进行了改造,改造后出炉温度命中率波动较大,严重影响了产品性能的稳定性。通过对出炉温度命中率主要影响因素的分析,从点火电极的阳极与阴极之间距离变化、UV探头失效分析及内外温差导致烧嘴损坏三个方面提出了解决方案,实现了出炉温度命中率的大幅提升。

关键词:出炉温度命中率;烧嘴;UV探头

PRACTICE STUDY ON THE IMPROVEMENT OF THE MEDIUM THICK PLATE QUENCHING FURNACE HEATING TEMPERATURE HIT RATE

Wang Lijian Wang Kun Yan Zhiping

(Shougang Jingtang Iron & Steel Joint Co., Ltd. Tangshan 063200,China)

Abstract:The combustion system of a company quenching furnace is transformed according to the change in the gas type, the large fluctuation of heating temperature hit rate was found after transforming, seriously affect the stability of product performance. In this paper, through analysis of the main factors that influence heating temperature hit rate,the solutions are put forward from three aspects: distance change between the anode and cathode of ignition electrode,failure analysis for UV detector and burner damage caused by temperature difference between inside and outside, realized that the hit rate of heating temperature increase greatly.

Key words: heating temperature hit rate; burner; UV detector

0 前 言

某公司为了大力推进绿色循环经济、节约生产成本,对现有中厚板淬火炉进行改造,充分利用自产高炉、转炉煤气以替代商采天然气,混合煤气吨钢燃料成本比天然气要低70元左右,但是燃气热值由8 000 kcal/Nm3降低至2 200 kcal/Nm3。(剩余3683字)