冶炼低碳钢RH炉环节的碳氧反应研究

打开文本图片集

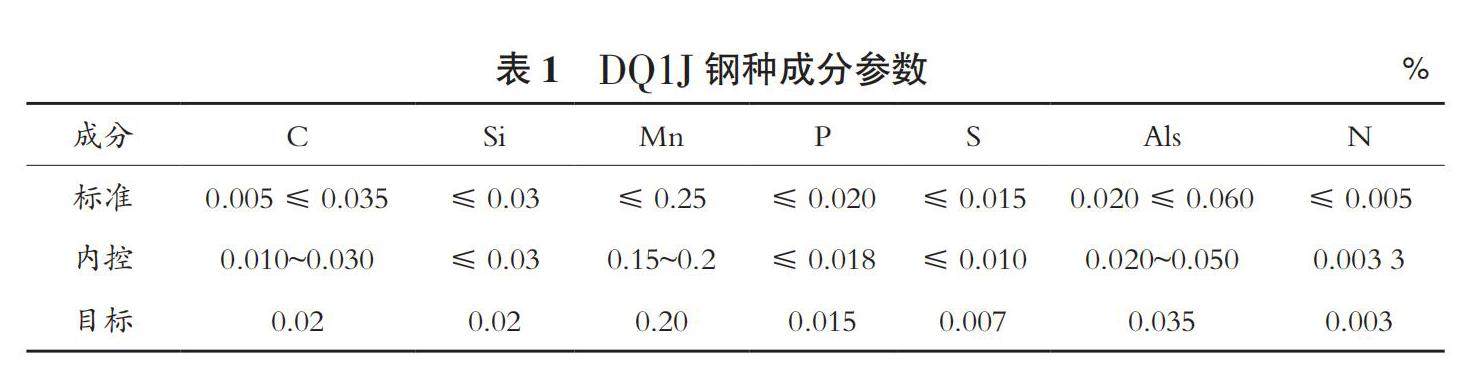

摘 要:为降低低碳钢的冶炼成本,提高低碳钢冶炼质量,可通过优化RH工艺参数,充分利用碳氧反应,加入碳粒,去除部分游离氧以代替铝脱氧,减少钢水中Al2O3夹杂的含量,提高钢水纯净度,降低吨钢成本;通过改变预抽模式,优化驱动气体的操作工艺,有效保护设备,降低维修成本,并为冶炼优质低碳钢水打下基础。

关键词:碳氧反应;低碳钢;真空度;脱氧;纯净度

STUDY ON THE CARBON OXYGEN REACT OF LOW-CARBON STEEL IN RH FURNACE

Qiu Wen Li Baolong Chang Jun Luo Hongyan Liu Zhenhai Liu Quansheng

(Beiying Steel-making plant of BX Steel. Benxi 117017,China)

Abstract:In order to lower melting cost for low carbon steel, RH process parameters were optimized. Carbon oxygen reaction was fully utilized and carbon particles were added to remove partial free oxygen to substitute aluminum to deoxidize. The content of Al2O3 inclusion was reduced and steel cleanliness improved, reducing tonnage steel cost. Through changing pre-vacuuming style and optimizing the operation process of driving gas, splashing was curbed and equipment effectively protected, reducing maintenance cost.

Key words: carbon oxygen reaction;low carbon steel;vacuum;deoxidize;cleanliness

0 引 言

低碳钢具有优秀的塑、韧性,一般可轧成钢管、钢带、钢板或角钢、槽钢、工字钢等复杂断面结构件,用于制作各种建筑构件、容器、箱体、炉体和农机具等。(剩余2735字)