锌铝镁冲压后表面黑点缺陷原因分析

打开文本图片集

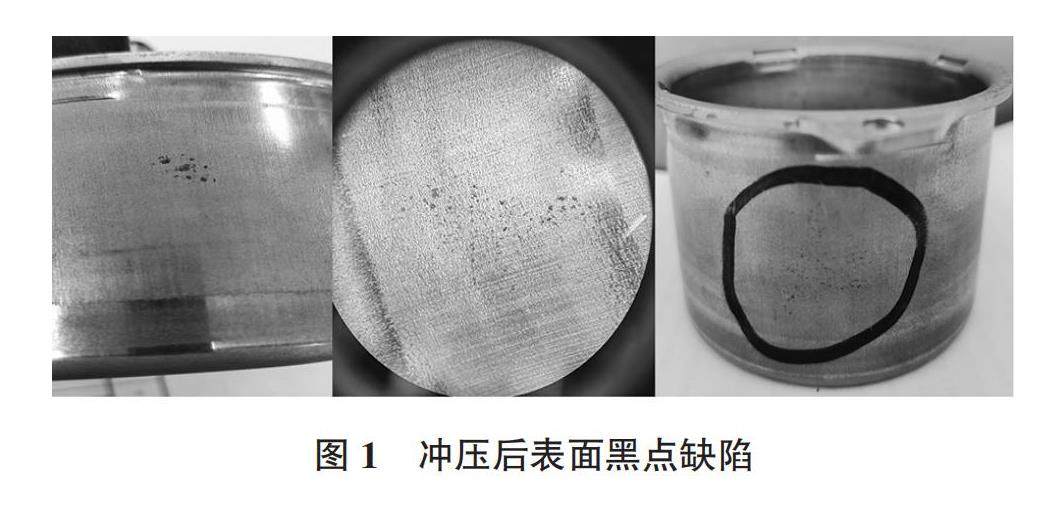

摘 要:针对唐钢镀锌铝镁板在冲压过程中出现的表面黑点现象,使用光学显微镜(OM)、扫描电子显微镜(SEM)及能谱仪等检测仪器进行检测,分析其冲压后表面出现黑点的原因,结果表明,在锌铝镁镀层钢板冲压过程中,镀层开裂,润滑油夹杂着异物颗粒在宽裂纹处聚集,表现为黑点缺陷。

关键词:镀锌铝镁板;冲压件;裂纹;黑点

CAUSE ANALYSIS OF ZAM SURFACE BLACK SPOT DEFECT AFTER STAMPING

Wei Huanjun Zhang Chunhua Tian Xiugang Mei Shuwen Guojian

(Tangshan Iron and Steel Group Co.,Ltd. Tangshan 063000,China)

Abstract:In response to the phenomenon of black spots on the surface of hot-dip galvanized aluminum magnesium plates of Tangshan Iron and Steel during the stamping process, detection instruments such as optical microscopy (OM), scanning electron microscopy (SEM), and energy dispersive spectroscopy were used to analyze the reasons for the appearance of black spots on the surface after stamping. The results showed that during the stamping process of hot-dip galvanized aluminum magnesium coated steel plates, the coating cracked, and lubricating oil mixed with foreign particles gathered at the wide cracks, resulting in black spot defects.

Key words: galvanized aluminum magnesium sheet; stamping parts; crack; black spot

0 前 言

锌铝镁镀层耐腐蚀性能优异,且有切口自愈性,其耐腐蚀效果相当于热浸镀锌钢板的15倍,相当于热浸镀锌铝合金钢板的5倍 ~ 8倍,且耐红锈性高,此外ZAM镀层硬度高,其维氏硬度为140 ~ 160 HV[1],具有卓越的耐磨损性。(剩余2737字)